Bayerische Moteren Werke AG (BMW), producer of luxury automobiles and motorcycles, is on the last stages of constructing a new automotive manufacturing facility in San Luis Potosi, Mexico.

Bayerische Moteren Werke AG (BMW), producer of luxury automobiles and motorcycles, is on the last stages of constructing a new automotive manufacturing facility in San Luis Potosi, Mexico.

Before robotics and assembly lines start the production of the 3 Series sedan models, BMW’s Building Information Modelling (BIM) standards require an accurate as-built documentation of all the architectural, structural and mechanical, electrical and plumbing (MEP) systems, and production line equipment.

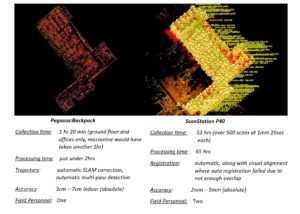

Being a consultant for BMW in a team including Constructora Chufani and Dasoft construction companies, I recommended a dual-sensor approach combining the Leica ScanStation P40 laser scanner and the Leica Pegasus:Backpack mobile mapping solution technologies.

The P40 provides 2-4 millimetre (mm) relative accuracy at a wide range of distances (e.g., from 0.3 – 270 metres) – a level of accuracy required by BMW’s BIM standard to achieve meaningful clash detection. The Pegasus:Backpack brings rapid mobile data collection to achieve time critical validation of in-place robotics to verify completion to all disciplines, and provides rich, visual data for asset management now and through the plant’s lifecycle.

Benefits of using dual sensors

Benefiting from the Pegasus:Backpack’s speed in both data acquisition and processing, one day walk-through collection was enough for the team to deliver to BMW a 7 centimetre (cm) absolute accurate 3D point cloud data combined with panoramic imagery (imagery at one-meter intervals along the trajectory) of the 70,000 square metre (m2) facility.

The data collected with ScanStation P40 consisted of over 500 scans; scanning and processing was completed in only three weeks. When performing over 500 setups, these are generally good scan and processing times.

When critically accurate as-built data was needed at priority, the team pinpointed these areas from the Pegasus:Backpack imagery and deployed P40 for a few one minute 26 second scans, then used Leica Cyclone Register software to add data to the model.

When critically accurate as-built data was needed at priority, the team pinpointed these areas from the Pegasus:Backpack imagery and deployed P40 for a few one minute 26 second scans, then used Leica Cyclone Register software to add data to the model.

Office processing

For the Pegasus:Backpack data processing, Leica Pegasus Manager software operated as a one-stop processing engine to produce the SLAM (Simultaneous Localisation and Mapping) corrected trajectory, along with panoramic imagery and coloured point clouds. The team chose Cyclone Register to process P40 data due to its robustness and ability to import Pegasus:Backpack data into one combined georeferenced point cloud.

Validating and clash detecting

The team also combined the Pegasus Manager’s free viewer (for validating of the panoramic imagery only) with Cyclone’s new PPM Suite. This bundle made sense since BIM across all disciplines was entirely done in Autodesk® AutoCAD ®, Navisworks ® and Revit®. The Leica software CloudWorx® family of products allows direct point cloud viewing and clash detection and reporting, while the JetStream component supercharged the point cloud importation and navigation to minimise time spent on these two typical hold-ups.

Summary

BMW’s manufacturing facility as-built documentation was a large, highly complex BIM project which was completed faster than any project I have seen or been involved in before and at short notice! I don’t believe that any other combination of hardware, software, support, and training would have gotten the same results at the speeds our team managed to delivered.

When it has to be right, you need to choose a vendor that delivers integrated solutions, at the speed needed by your business, and guarantees the expertise to guide you to a successful result.

Frank Collazo

MED (Mobile 3D) Reality Capture Consultant at Leica Geosystems AG