Safety isn’t expensive, its priceless. ~Author unknown

There are potential dangers in any construction site. Unfortunately, accidents in construction sites are too common. According to the United States Department of Labour, the fatal injury rate is higher for the construction industry than the national average in this category for all industries.

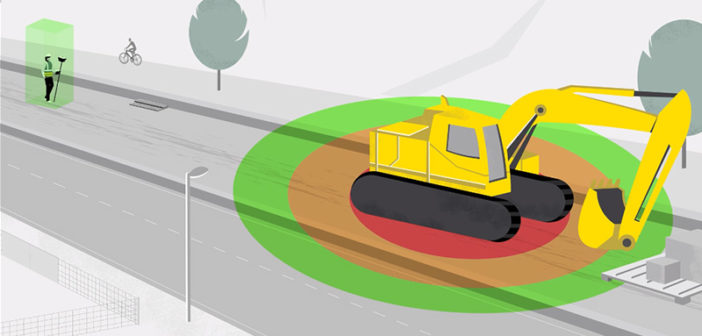

Employers and workers need to create a safe work environment and take an active role in mitigating hazards. Leica Geosystems solutions not only contribute to build safer, well-built environments and monitor their safety, but also contribute in making construction sites safer by providing solutions that reduce human exposure to hazards.

UAV-based surveying systems help to map and capture digitally dangerous terrains from above. Where unstable terrains pose a risk for surveyors UAVs can fly freely while the operator collects data from a safe location. For instance, Spatial Technologies used the Aibot X6 to survey a mine in Papa New Guinea to provide visual documentation of volume changes in the spill grounds on an environment that would be risky for any surveyor.

UAV-based surveying systems help to map and capture digitally dangerous terrains from above. Where unstable terrains pose a risk for surveyors UAVs can fly freely while the operator collects data from a safe location. For instance, Spatial Technologies used the Aibot X6 to survey a mine in Papa New Guinea to provide visual documentation of volume changes in the spill grounds on an environment that would be risky for any surveyor.

“As the dangerous terrain evokes risky conditions for surveyors, measurements were previously being taken few and far between. With the safer and quicker UAV survey, the mine survey team can now monitor on a more regular basis to manage issues sooner and rectify problems before they become major concerns.”

Mobile mapping applications combining imaging and LiDAR technology acquire information quickly and without making physical contact, hence, reducing the chances of getting injured or exposed to hazards. Capturing the entire infrastructure of the world’s longest traffic tunnel, the Gotthard Base Tunnel, while it was under construction was possible thanks to the Leica:Pegasus Two, a vehicle-independent mobile mapping solution that captures the full 360° spherical view imaging and LiDAR together.

“By constantly capturing data on the move without disrupting ongoing construction, safety increased for Grunder Ingenieure AG and other employees. No longer were the surveying engineers required to trapeze through a risk-filled construction site, and construction workers no longer needed to worry about avoiding surveyors or instruments set up in the midst of their site.”

Laser scanning captures physical environments through millions of points that are converted into 3D models that allow specialist to analyse any structure without having physical contact. An example of this is how Sertogal SL measured with millimetric accuracy the distances, angles and areas of an electrical substation in Spain using a Leica Geosystems Scan Station.

Laser scanning captures physical environments through millions of points that are converted into 3D models that allow specialist to analyse any structure without having physical contact. An example of this is how Sertogal SL measured with millimetric accuracy the distances, angles and areas of an electrical substation in Spain using a Leica Geosystems Scan Station.

“The laser scanner allowed us to capture the substation without entering in dangerous high voltage areas with risks. The great precision and lack of noise in the generated point clouds permitted us to work in a complex structure with metallic elements and grids to obtain a BIM model that is a true representation of reality.”

Beyond laser scanning and LiDAR technology, Leica Geosystems utility detection solutions and GNSS systems and reference stations enable engineers to locate buried utilities invisible to the human eye. It is of vital importance to know the exact location of all buried assets to avoid striking utilities that beyond damaging structure can injure workers.

To construct the Riyhad metro project, the first metro lines in Saudi Arabia, a team of surveyors was able to precisely locate all buried utilities to avoid dangerous utility strikes and to integrate them to the metro design. In addition to the surveying tasks preformed by the team, the surveyors could also monitor the safety of the ongoing construction and the impact of the excavation on the surrounding areas with a Robotic Total Station.

To construct the Riyhad metro project, the first metro lines in Saudi Arabia, a team of surveyors was able to precisely locate all buried utilities to avoid dangerous utility strikes and to integrate them to the metro design. In addition to the surveying tasks preformed by the team, the surveyors could also monitor the safety of the ongoing construction and the impact of the excavation on the surrounding areas with a Robotic Total Station.

“With the accuracy of the Leica TM50 total station, we were able to quickly determine if construction operations were negatively impacting surrounding structures. Improving the safety for the crew and community, our work has been well received here in Riyadh.”

Leica Geosystems’ portfolio of solutions that can improve safety on site goes beyond hardware. Smarter software solutions can increase collaboration on site and help operators to improve workflows and remove handicaps by automating processes. To pave India’s longest tunnel road, New India Structures Pvt. Ltd. moved away from the conventional methodology of setting up of stringlines that occupy space, halt vehicular movement and pose a serious safety hazard for the personnel working on-site. Leica PaveSmart 3D made possible for them to have a stringless solution that could operate inside the restricted area of the tunnel.

Leica Geosystems’ portfolio of solutions that can improve safety on site goes beyond hardware. Smarter software solutions can increase collaboration on site and help operators to improve workflows and remove handicaps by automating processes. To pave India’s longest tunnel road, New India Structures Pvt. Ltd. moved away from the conventional methodology of setting up of stringlines that occupy space, halt vehicular movement and pose a serious safety hazard for the personnel working on-site. Leica PaveSmart 3D made possible for them to have a stringless solution that could operate inside the restricted area of the tunnel.

Counting with reliable solutions that capture, measure and monitor sites have benefits beyond efficiency, ROI and reducing worktime – it also means “safety first”.

Visit Pure Surveying – Shaping every phase of construction and get inspired to deliver civil engineering surveying services on time and within budget while reducing waste and increasing safety in every construction phase.

Renata Barradas is the Communications Manager for Hexagon Geosystems