The days of blueprints and spending hours measuring as-builts are over. With laser scanning, high-detail point clouds can be quickly referenced with something as easy as a few clicks on a computer or taps on a mobile device. No more costly delays due to flawed measurements—it’s all there in the point cloud.

Element6, a Georgetown, Ontario, Canada-based boutique engineering consulting firm has built a reputation providing fast and cost-effective service to clients in the speciality chemicals industry. With record speeds –in one case as quickly as 12 hours after the initial call- Element6 delivers the requested data to the client.

Based on Element6’s success, read below 5 tips you can apply to take your engineering firm to the next level:

![]()

1. Have an all-digital approach

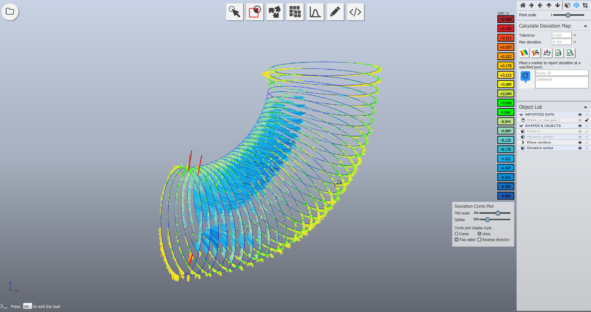

Element6 relies on a lean, fully digital approach to plant engineering and design that makes all the difference when time is of the essence. To deliver low-cost, high-quality, high-speed service, the team uses an all-digital approach they call Virtual Plant Design (VPD). The firm begins with a digital point cloud of the as-built conditions, captured with high-accuracy laser scanning, which helps them quickly find the solution to issues regarding plant renovations, process optimisation, new equipment installations, or whatever challenges the clients face.

Element6 relies on a lean, fully digital approach to plant engineering and design that makes all the difference when time is of the essence. To deliver low-cost, high-quality, high-speed service, the team uses an all-digital approach they call Virtual Plant Design (VPD). The firm begins with a digital point cloud of the as-built conditions, captured with high-accuracy laser scanning, which helps them quickly find the solution to issues regarding plant renovations, process optimisation, new equipment installations, or whatever challenges the clients face.

Having an accurate and up-to-date 3D point cloud as-built gives instant access to measurement data and enables Element6 to work with its clients remotely to identify solutions and avoid downtime. The ability to create deliverables that are much more informative permits Element6 to perform work in weeks or even days that would traditionally have taken months.

2. Invest and do things in-house

While some engineering consulting firms prefer to rent their technology on an as-needed basis, Element6 has strategically invested in several scanners, including a professional-grade Leica ScanStation P30, a Leica BLK360 imaging laser scanner, and, most recently, two Leica RTC360 portable, automated, high-speed laser scanners that capture complete scans with high-dynamic-range (HDR) imagery in less than two minutes and automatically pre-register the scans in the field with Cyclone FIELD 360. The company also handles its own point cloud processing using Leica Cyclone software, along with Leica JetStream and Leica CloudWorx for easy CAD integration, and Leica TruView for easy client visualisation.

Purchasing the technology instead of renting it has enabled Element6 to become experts in capturing and using point clouds—which, in turn, allows the company to offer unexpected benefits to its clients.

3. Start projects immediately to reduce project turnaround time

In a traditional approach, an initial consultation would be followed by a proposal and then a return to the site to capture as-built conditions before work could begin.

Element6 often brings one of its RTC360 laser scanners to the first meeting and captures 10 or 20 scans onsite in a matter of minutes. The scanning and registration are done so quickly that the firm is often able to begin work on the project immediately, significantly reducing turnaround time.

Instead of waiting for engineers to travel to their site, clients can work with Element6 consultants remotely to identify solutions and avoid downtime. The ability to offer high-speed scanning with the Leica RTC360 laser scanner enables Element6 to significantly reduce project turnaround time.

4. Find a business model that constantly challenges your company

Element6 is centred around accountability and a results-oriented approach. Element6 spends time upfront identifying exactly what the client needs and then sets a price based on the service that will be required—not the amount of time required to complete the work.

This fixed-price model radically sets Element6 apart from other engineering consulting firms. This business model constantly challenges the company to find new ways to be faster, more innovative, and more focused on meeting the client’s needs.

5. When purchasing technology consider not just the hardware capabilities but the complete field-to-finish workflow, the support provided by the manufacturer, and the track record of innovation

When making technology decisions, Element6 knows it isn’t just buying a product. “Leica Geosystems has industry-leading hardware, but it also has a fully integrated workflow and a commitment to reliable service and continued innovation,” said Rob Jickling, Element6’s consulting principal. “We rely on Leica Geosystems as a partner that will help us stay on the leading edge.”

This partnership builds confidence into the company’s operations and enables Element6 to provide clients with outstanding service.

With laser scanning, Element6 produces high-detail virtual point clouds of engineering plants that can be quickly referenced with something as easy as a few clicks on a computer or taps on a mobile device. An innovative business model, paired up with the right laser scanning solution and trusted partner support, has set this firm apart and furthered its success.

Read the full case study “How Element6 delivers the future of plant engineering with laser scanning.”

Learn more about how to grow your business with 3D laser scanning.