Scanning brings an additional dimension to monitoring, opening new areas that were in the past only reachable with reflectorless measurements. With scanning, one reflectorless measurement is replaced by hundreds or thousands of them in the scanned area, bringing millimetre accuracy on flat surfaces. This method, proven with median results over months, delivers reliable measurements and a robust monitoring system.

6 years of scanning in GeoMoS

A scanning option was implemented in GeoMoS Monitoring Solution in 2013, following the release of the MultiStation MS50. This was the first automatic scanning solution in monitoring and remains the only one in the market.

Since 2013, as technology has developed, a new MultiStation flagship was released – the MS60 world’s first self-learning MultiStation. The MS60, together with Leica GeoMoS Software Suite, has been continuously enhancing with every release by adding new functionalities and further improving the scanning feature.

How does scanning in monitoring work?

Scanning for monitoring is based on user-defined surfaces (georeferenced scan areas) that are automatically scanned respecting the measurement cycle schedule as a part of automated 24/7 deformation monitoring. After each scan, the sophisticated algorithm using n.Vec technology is applied to process the scan cloud, compare it to the reference scan and calculate the deformation.

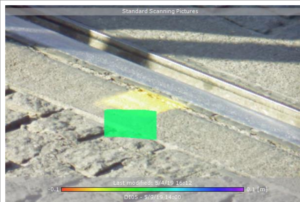

The image above shows the colour-coded deformation heat map.

Displacements are calculated perpendicularly to the surface, allowing the user to configure alarm thresholds with respect to normal vector values. The users receive real-time messages in case limits are exceeded and can make informed decisions immediately. Data visualisation is available in the form of heat maps, showing colour-coded deformations and timeline graphs displaying point cloud statistical values of:

- Median deformation

- Maximum deformation

- Deformation volume.

In practice, scanning is often combined with 3D prism monitoring and imaging. Prism measurements are typically used for reference groups, guaranteeing the stability of the instrument setup, whereas scanning is measuring a monitored area. A high-resolution dual-camera imaging system automatically captures images with each scan, allowing users to have complete information for every epoch.

What kind of accuracy can be achieved?

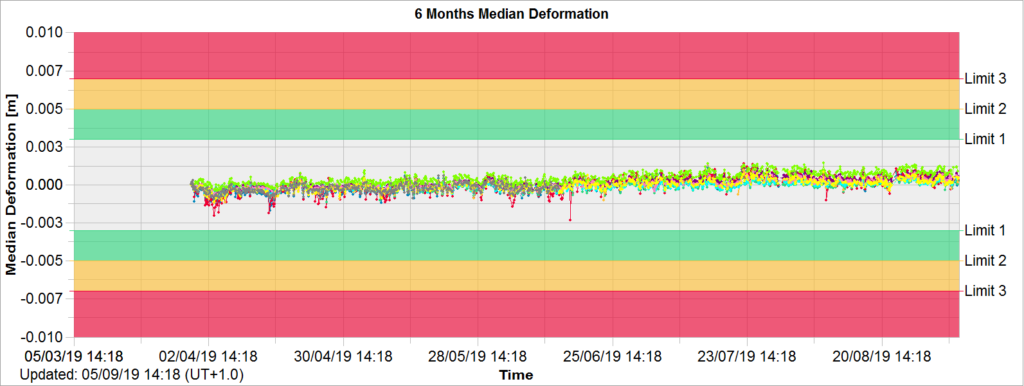

Result analysis from dozens of installations worldwide shows the MS60+GeoMoS solution delivers 1 to 2 mm level accuracy within 100-150 m distances, with extreme reliability and repeatability of the data. This is essentially the same level of accuracy typically expected with prism monitoring in the same conditions.

The graph shows the median deformation over six months of scanning in a public area. Median deformation is calculated from every deformation value in the scanned cloud. It’s resistant to possible existing outliers in the result and can be observed in long-term scanning for monitoring.

Why use scanning?

The answer is simplicity. When compared to prism monitoring or geotechnical monitoring, automatic scanning simplifies:

- Ordering – only one piece of hardware and one software option are needed to be ordered: MS60 and GeoMoS Monitor Option 4 – In addition, customers and designers do not have any more to estimate the right number of monitoring prisms, the targets are virtually infinite

- Installation – scanning brings time and cost savings, especially in urban areas because:

- There is no need to choose discrete points

- There is no need to ask for permissions and access to install equipment on the monitored object

- Operation – further time and cost savings due to no equipment to maintain on-site (e.g. no prisms cleaning, no sensors checks).

- Interpretation – there is no need for additional computations, scanning results are immediately available by using heat maps, graphs and tables.

- Project end – when the project ends, there is no need for dismantling prisms on monitored points. MS60 is simply moved to another project, bringing additional time and cost savings.

When to use scanning?

Up until now, scanning for monitoring has found its main application in buildings and road surfaces, but it’s applied to other structures as well. Due to different reasons, it’s often impossible to mount the prisms in a monitored area, e.g. to historic buildings, roads, in protected areas. In such cases, scanning is a perfect solution as the surfaces are monitored “contactless”.

Case studies from Singapore and Dublin are great examples of tracking road settlements with scanning, due to TBM excavation below the highway and construction site nearby the light rail. By creating a grid of scan areas on the road surface, scanning delivers reliable results even under heavy traffic. The same workflow as in Dublin was also adopted for the enabling works of the HS2, a planned high-speed railway in the United Kingdom.

Tritech Engineering & Testing (S) Pte Ltd was contracted to monitor the road surface during the construction of Mass Rapid Transit (MRT) System by the Singapore Land Transport Authority’s (LTA). Tritech used a fully automated monitoring system on a real-time basis.

To minimise current and future concerns related to safety and structural integrity of Luas, Datum Monitoring Ireland, analysed the data of the dual Luas light railway system continuously using two Leica Nova MS60 MultiStations, one LS15 digital level and GeoMoS monitoring software.

Another use case is the scanning of buildings and other structures, due to excavations under or nearby them. By defining small scan areas (patches) on the front area, side area and overhang of the buildings (three areas nearby on perpendicular surfaces) or any other structure, displacements in three dimensions can be monitored.

Scanning of geotechnical faults in mines and rockfall areas brings another example of scanning for monitoring. With a range up to 300 m, the MS60 delivers highly accurate scans used to detect deformations perpendicular to the surface.

Find out how to use geodetic, geotechnical and meteorological sensors with fully-customisable software in monitoring.

Learn more about Monitoring Solutions and GeoMoS Monitoring Solution.

Lidija Spiranec – Application Engineer Monitoring Solutions

Marco Di Mauro – Monitoring and Control Segment Manager for Leica Geosystems