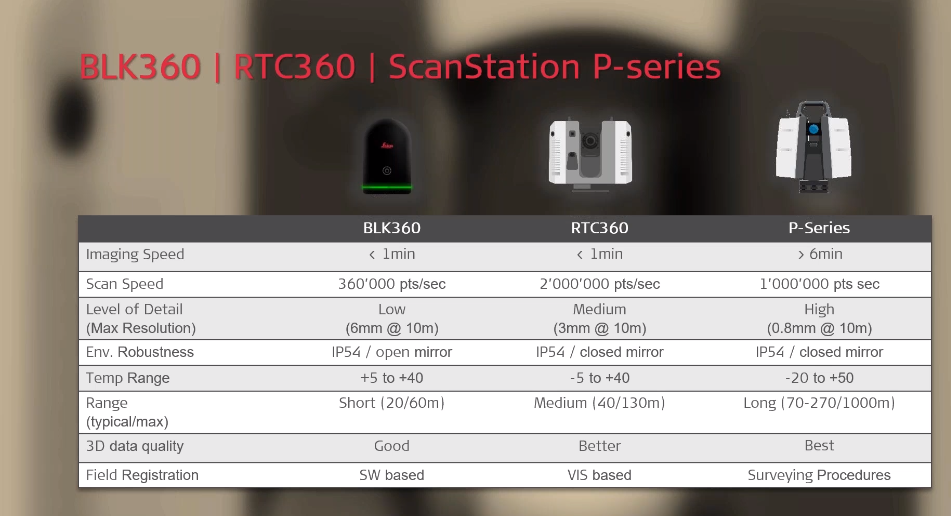

Have you been wondering which laser scanner is the right one for your projects? Whether you have your eyes on the Leica BLK360 imaging laser scanner, the Leica RTC360 3D laser scanner or the Leica Scan Station P-Series, this blog will exemplify the diverse range of projects you can do with a laser scanner and how laser scanners can work in conjunction.

BDM uses the BLK360, the RTC360 and the P-Series. According to Brandsma, the most important differences are the range, the 3D data quality and the on-board real-time dual-axis compensator available in the P-Series.

Rein Brandsma, founder and director of Brandsma Digitaal Meten (BDM), a Dutch company specialised in Digital Surveying for Construction, Industry and Civil, demonstrates during the Field-to-Finish efficiency using ground-breaking solutions from Leica Geosystems webinar how BDM is getting the most out of their reality capture solutions.

Through seven exciting projects, Brandsma presented why BDM uses reality capture and how they choose the right laser scanner for each task and when to combine them. We present five of those projects to help you choose the right laser scanner for your job:

Project 1: Extending a ship

The three-mast sailing ship Antigua, built in 1957, transported passengers through the Arctic and around the world. Its owners wanted to extend the middle of the ship to accommodate extra sleeping cabins. Its small cabins and insides were the perfect match for the portable and light BLK360. BDM laser scanned the exterior with the ScanStation P40 and combined the scans with Leica Cyclone 3D point cloud processing software.

- Mesh of the ship

- BDM scanned the exterior with the P40, the interior with the BLK360 and combined the scans with Cyclone software

- The extension part of the ship

“The point cloud was imported, and the mesh was created with 3DReshaper, making every detail visible. What is on the ship is also in the point cloud. We made cross sections and we can export the cross sections to a CAD software,” explains Brandsma. “When the extension part was ready, the ship came back, and the extension part fitted in between straight away. This saved the client quite a lot of time.”

Project 2: Scanning and modelling an entire building

BDM was requested to scan the city hall, including the building surroundings, of a town in the Netherlands. In total, 1000 scans from seven buildings were generated using the RTC360 and the ScanStation P40. BDM used the RTC360 due to the distance between the buildings.

- TruView of the town centre

- Point cloud of the town centre

- 3D model of the town centre

- Blueprint of the town centre’s buildings

“The point cloud was all measured from the ground surveys. To measure the roof, you don’t have to go on the roof. Even the details on the roof adjust from one scan from the ground surveys,” explains Brandsma. “With the RTC360 it only takes 1 or 2 minutes and it straight away makes another scan. The intelligent software recognises if there are moving objects and it removes it from the point cloud.”

Depending on the needs of the client, low or high detail is requested. Based on the client’s request, BDM created a 3D model with low detail. “Once the scan is made you can always go back to the point cloud and bring more detail with the 3D model. When a 3D model is ready you can simply convert it to a 2D drawing and make a layout with dimensions,” adds Brandsma.

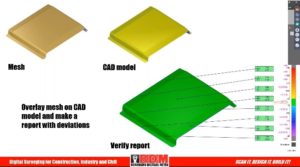

Project 3: Scanning a plug and mould to verify with CAD model

BDM laser scanned plugs used for moulds. Since the dimensions of the plugs must be perfect because the parts are used for the moulds, BDM used the ScanStation P40 to achieve the highest accuracy. Using the ‘area scan’ option of the P40, an expert laser scanned just the area of the moulds instead of the entire surroundings. “The targets were recognised in Cyclone and it is also possible to do a setup with the P40 in the field and make a loop around the object,” adds Brandsma.

- Point cloud of the mould

- Overlay mesh on CAD model and report with deviations

The scans were registered with Cyclone and exported into Cyclone 3DR to create a mesh. The client delivered the CAD models and BDM created an overlay on the CAD model to create a deviation report.

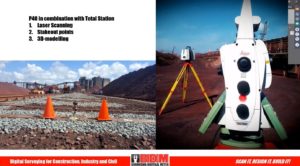

Project 4: Rotterdam EECV: kilometre-long conveyor belt

BDM measured a kilometre-long conveyor belt, one of the longest in the world. Bordered by a canal, EECV is Rotterdam’s most important terminal for the throughput of dry bulk. BDM measured the conveyor belt with a total station and scanned three sections of the conveyor belt. The need to scan long distances led BDM to choose the ScanStation P40 for this job. Experts used a total station in combination with the P40 to complete laser scanning, stakeout points and ultimately 3D modelling.

“We used ground control points along the 950 metres. We use the Leica TS60 total station – it has a 0.5 angular accuracy. Then we made ground control points in the three areas we needed to scan and imported those ground control points into the scanner with the right coordinate system,” explains Brandsma.

- BDM used the P40 in combination with total stations

- Conveyor belt scanned by BDM

Besides scanning, BDM also is often asked to do stakeout work. With the total station, experts staked out the structure points and the foundation of the structured lines for the railway and the beams underneath.

Project 5: Scanning and modelling a plant

BDM scanned a plant located in Austria with an approximated area of 200×200 metres using the RTC360 and ScanStation P40 laser scanners. To laser scan the inside of the plant, BDM chose the RTC360 for its speed, portability, High-Dynamic Range (HDR) imagery and automated pre-registration in the field. For the outside of the plant, BDM used the P40 to reach long distances and to do some detail scans.

- Plant facility in Austria scanned with the RTC360 and the P40. BDM Modelled the existing parts in Revit and Cyclone.

- BDM experts linked and overlaid the 3D design model (parts in green) from the client into their model to see the clashes and to ensure it would perfectly fit.

BDM modelled the existing parts in Autodesk Revit and Cyclone. BDM experts linked and overlaid the 3D design model (parts in green) from the client into their model to see the clashes and to ensure it would perfectly fit. To be able to see any clashes before pieces are on site, and even before production starts, helps clients save time and money.

Bottom line: It depends on the job

When asked during the Q&A of the webinar which laser scanner Brandsma prefers to use and why, the company owner concluded, “It depends on the job you have to scan. If you are using long-range scanning and high-accurate data, you should use the P40. If you don’t have to do any land surveying options, then RTC360 is perfect.”

To finalise Brandsma pointed out: 1) the HDR imaging, speed and in-field pre-registration as his favourite features of the RTC360; 2) the simplicity to integrate survey data and scan data into a single project with a ScanStation; and 3) the benefits of using Universal Project file (LGS) format as users have the flexibility to exchange data from Cyclone between all Leica Geosystems laser scanning software.

Read more about how Brandsma Digitaal Meten is getting the most of its reality capture solutions in this blog and in this customer profile.

Watch the webinar Field-to-Finish efficiency using ground-breaking solutions from Leica Geosystems and discover more details and reality capture projects.