Manufacturers and industrial plants are under pressure to deliver, adapt and innovate in today’s challenging environments. Instant access to accurate data is more important than ever in facilitating critical decision-making, cutting downtime, boosting production efforts and informing longer-term planning. Having confidence in this data and being able to access it remotely from any location empowers teams to keep their business moving even when they can’t be onsite.

Advances in 3D laser scanning technology mean that capturing and accessing accurate data has never been simpler. Here are just some of the key benefits of 3D laser scanning technology

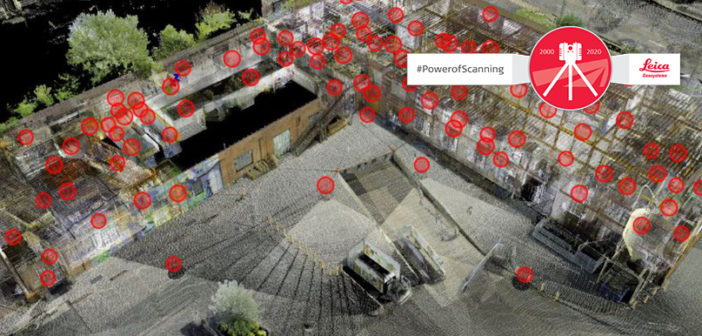

- Simple, accurate data capture – operated by a single worker, 3D laser scanners can accurately capture millions of measurement points to create a comprehensive, clear and precise digital record of a plant – from the exact location of valves and piping to the condition of conveyors and lines – that can be used for analysis in planning for both operations and maintenance.

- Data capture in an instant – 3D laser scanning is fast. Instead of taking weeks or hours using more traditional measurement methods, the fastest laser scanner available can create a comprehensive, accurate, as-built scan in as little as 26 seconds.

- Easy access to data anywhere – once the data is captured, cloud-based software gives project collaborators instant access to the data from anywhere on any device – even those that aren’t familiar with CAD or 3D datasets. Software advances let collaborators effectively visit the site virtually in real time. There, they can take snapshots, make measurements, create visualisations, and create markups with tags that contain useful notes and project context all with applicable security.

- Agile and remote project management – throughout the lifecycle of a project, onsite and offsite collaborators can use cloud software to access, view and analyse work as it progresses. They can provide feedback to ensure that all areas of interest have been captured to project specifications, and point cloud data including tags can be shared directly from the field to provide a dimensionally correct and photorealistic view of the plant as developments happen.

- Centralised security control – project managers – or any nominated collaborators – can maintain full control over who sees what data and when, and who is able to make changes, even those that are offsite.

- Innovation to succeed and thrive – having access to such deep, rich, accurate information can facilitate innovation, which is essential in manufacturing and industrial settings as organisations strive to adapt to the ever-evolving landscape. The way we think about and apply these solutions remains our most powerful resource in making industrial plants lean, agile and easily accessible in a virtual environment, which can then be easily replicated in the physical environment.

With these benefits in mind and the uncertainty of the future, now is the perfect time for organisations to develop a strategy for new ways of thinking and working to ensure they thrive in the future.

Contact us to talk about your ideas or learn more about how 3D data can help maximise your plant operations.

Mr. Joel Hurt, Vice President – Industrial Plant Solutions | USA/Canada with Leica Geosystems, leads a team of subject matter experts responsible for and specialising in technology solutions for the industrial plant industry. Mr. Hurt has been a global leader in developing and driving laser scanning technology for over 15 years. Prior to Leica Geosystems Joel was the President and COO of VisiImage, also specialising in laser technology. Additionally Mr. Hurt has worked extensively in the engineering design industry. Joel executed key roles with major Engineering, companies on projects around world; with 20 plus years with Bechtel, Raytheon and Jacobs Engineering. Mr. Hurt, a Mechanical Engineer, an alumnus of Texas Southern University, brings a vast amount of practical real-world field experience as well as insight as a leading-edge technological innovator.

Mr. Joel Hurt, Vice President – Industrial Plant Solutions | USA/Canada with Leica Geosystems, leads a team of subject matter experts responsible for and specialising in technology solutions for the industrial plant industry. Mr. Hurt has been a global leader in developing and driving laser scanning technology for over 15 years. Prior to Leica Geosystems Joel was the President and COO of VisiImage, also specialising in laser technology. Additionally Mr. Hurt has worked extensively in the engineering design industry. Joel executed key roles with major Engineering, companies on projects around world; with 20 plus years with Bechtel, Raytheon and Jacobs Engineering. Mr. Hurt, a Mechanical Engineer, an alumnus of Texas Southern University, brings a vast amount of practical real-world field experience as well as insight as a leading-edge technological innovator.