Surveying technology is constantly evolving, creating a landscape that can be both intriguing and confusing. Advances in 3D laser scanning technology over the last decade have enabled surveyors to quickly collect highly detailed information about a site and build 3D maps from point cloud data. But with options in scanning technology also expanding, choosing the best technology is not always straightforward.

If you have been thinking about moving into laser scanning to capture more business, this blog will help answer some questions about the best way to add point clouds to your existing workflows. We look at how choosing an all-around survey solution, which combines total station functionality with 3D laser scanning, can drive productivity; we also look at when you should consider a dedicated 3D laser scanner.

Introducing 3D laser scanning with an all-around solution

One way to add 3D laser scanning to your surveying services is to choose a total station with scanning capabilities. The Leica Nova MS60 is the world’s first MultiStation, which lets you perform all surveying tasks with one instrument.

It encompasses 3D laser scanning up to 30,000 points per second (Hz), allowing you to complete small-area scans quickly. Its efficient operation, different methods of collecting data and real-time analytics make it a tool that can be used every day to increase productivity. In addition, it boasts digital imaging technology, including an overview and a 30x magnifying telescope camera for accurate image assisted surveying both at the instrument and remotely.

When should I use a scanning total station vs a dedicated 3D laser scanner?

To figure out the best technology, it’s best to take a step back and analyse your business plan in detail.

Think about the types of projects you already work on. Most surveying firms already have projects that would be suitable for either a scanning total station or dedicated 3D laser scanner, but some specialise in activities where one type of technology has a clear benefit.

For example, if you perform a lot of boundary and topographic surveys, the MS60 MultiStation is a great instrument because it can be used every day for both types of projects. It’s essentially a multi-tool or Swiss army knife, where each aspect of the tool does what you need at that moment.

You can take advantage of the extreme accuracy and efficiency of the total station on boundary surveys and then use the scanning capabilities on the topographic projects to speed things up and keep your crew safe and out of harm’s way. Compared to carrying out traditional topographic surveys with a total station alone, the MS60 MultiStation is roughly four times faster.

Conversely, if you need to regularly scan large areas and want to offer 3D laser scanning as a stand-alone service, you’ll probably want a dedicated laser scanner to maximise speed and data capture. High-speed laser scanners like the Leica RTC360 can capture dense, high-quality scans with High-Dynamic Range (HDR) imagery in less than two minutes, which is substantially faster than either a total station or Multistation.

Workflow is another key consideration. Are you willing to make the necessary investments in systems and staff to manage the high volumes of data captured with a dedicated 3D laser scanner? If not, a better option might be to start more slowly with a Multistation, which uses traditional survey workflows, and grow your point cloud capabilities over time.

Additionally, consider how you want to use the point cloud data in the field. Recent software developments such as the Inspect Surface app for the MS60 and Rithm powered by JetStream make it easy to do data analysis onsite in addition to capturing as-built information.

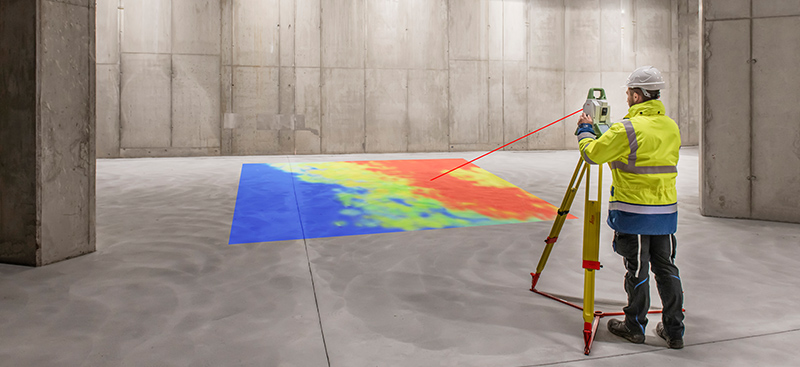

But if you do a lot of work with design files, you might find that the MS60’s Inspect Surface app gives you more capabilities in the field. For example, you can use design elevations, DTMs and IFC files to identify discrepancies from the design in real time for floor flatness or column placement, which can provide significant advantages in construction productivity and accuracy.

What should I look for in a scanning total station?

If you’ve decided a scanning total station is the best fit for your needs, the first capability to evaluate is the robotic total station’s performance. Figure out what the time on station looks like to determine an accurate value.

For instance, how quickly can you obtain measurements at the required accuracy? Is it a one-second instrument? Can it measure at extended ranges? Does it use automation (such as auto-height) to assist with setup, increase efficiency and further ensure accuracy?

With the 3D laser scanning functionality, evaluate the workflows rather than just the points per second speed. What workflows does the solution offer to help you work better? For example, if you occasionally need to do full dome scans, a band scanning function will allow you to complete these scans more efficiently. (If you perform a lot of full dome scans, you probably need a dedicated 3D laser scanner rather than a scanning total station.).

What should I expect from office software?

Scanning with either a dedicated laser scanner or scanning total station significantly streamlines and simplifies field work, but it does create some additional work that needs to be done in the office. Here, too, technology advances can have a big impact on efficiency and capabilities.

With scanning total stations, look for software that seamlessly connects the field and office and can handle data from a variety of sensors. For example, Leica Infinity Survey Software enables you to manage, process, analyse, quality check and share all field survey measurement data, including single point measurements from total stations, digital levels and GNSS receivers; photogrammetric measurements from visual positioning GNSS receivers and unmanned aerial vehicles (UAVs); and scan data from scanning total stations

Working with scan data from the MS60 in Infinity is straightforward. After data import, the scan data can be visualised in the graphical view along with the TPS measurements. You can make all required data edits and processing, including updating the setups position or orientation, correcting incorrect measurement height or prism, processing traverse or reducing multiple observations. The scan data position is automatically updated.

Once you’re happy with the data, it can be exported to various data formats and services for further downstream use in other software. For example, using Leica CloudWorx allows you to use AutoCAD, Bentley, or another programme you’re familiar with to develop your designs or CAD drawings for your customers.

Office software for dedicated 3D laser scanners has also advanced in recent years, so that many previously manual functions are now automated. Leica Cyclone REGISTER 360, for example, which is used to process data from the RTC360 laser scanner, uses simple, guided workflows, automated registration and one-click access to client-ready deliverables.

How can I use point clouds to grow my business?

Whether you decide to go with a scanning total station or dedicated laser scanner, training is key to maximising the value of your investment. From online learning courses and how-to videos help to virtual classroom sessions, training resources are widely available to help you incorporate point clouds into your business model and expand your services.

While it’s getting harder to find qualified field technicians, point cloud technology makes it easier to capture data that can be used in a wide variety of applications. With the right technology and strategy, surveyors can use laser scanning every day to improve safety, capture more data, and quickly complete field work.

The more you use laser scanning, the more opportunities you will see to grow your business with your scanning capabilities.

For more information, watch our on-demand webinar – The Easiest Way to Add Laser Scanning to Your Surveying Capabilities – which includes a field test with the MS60 MultiStation and advice on best practice workflows for scanning total stations.

Bob Kilburn (Survey and Engineering Product Applications Manager), Brian Elbe (Reality Capture Consultant), Bruce Marquis (Sales Representative Scanning)