Nelson Boquin set up his engineering survey company seven years ago, after seventeen years in the business. Nelson Surveys, based in Seaford, Australia, offers surveying services for some of South Australia’s largest infrastructure projects. Whether steel or concrete bridge constructions, building or road set outs, Nelson Surveys can tell you exactly what is on-site, supplying vital information for construction projects. A long-time Leica Geosystems customer, Boquin explains why investing in laser scanning technology is part of his growth strategy.

The business advantage: road reconstruction project case study

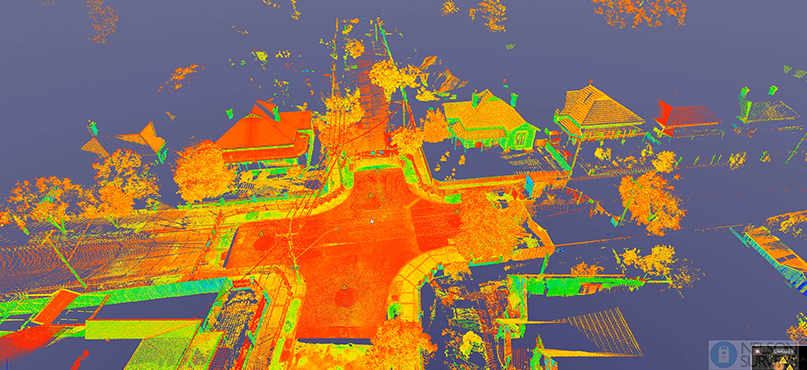

Put simply, there are situations where using a 3D laser scanner is the best approach, so being able to do it gives us an advantage. It also means we can show clients new types of deliverables. For example, we recently used the Leica ScanStation P30 to capture the 3D geometry of a road for a reconstruction project with a local council.

With data captured by a laser scanner, it’s easier to display parts of a surface that would otherwise be ignored. In this case, the roads surveyed had at times less than 0.2% fall, so are incredibly flat with features that are easy to miss. Both ourselves and the council were impressed with the level of detail that laser scanning technology delivered for them. Since that project, we have conducted other similar scans for the same client.

A complete picture: “Capture the entire area, not just sections”

There are times when it’s necessary to get a very high level of detail and laser scanning makes it easier to do this.

When the final road surface was constructed, we placed control points along the corridor to radiate to as we moved along with the traverse app onboard the ScanStation P30. This resulted in very accurate results, in fact, this has been the most accurate laser scanning solution I have used to date. Using a total station, we would have checked the road surface every 10 metres, meaning that areas in between those sections were ignored. With the ScanStation P30, the entire road surface was covered. Being able to capture the entire area, not just sections, meant we could capture much more valuable information and we were able to show how much more valuable information was captured using a laser scanner compared to a total station.

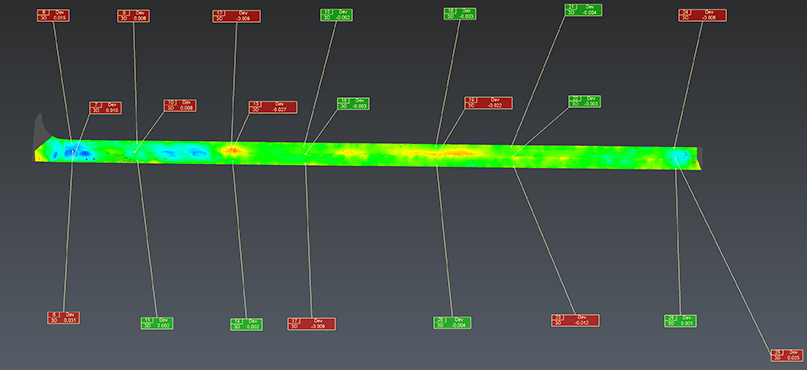

For us and the client, it meant that we were very quickly able to isolate problem areas on the surface without having to try and find them as we would have had to previously. We picked up problems that might not have been picked up at this stage using other methods – which means we pre-empted issues for the client. That’s a good position to be in as a supplier and partner.

High-speed scan rate and long-term time-savings

It took us one and a half hours to complete the survey with the ScanStation P30, including images and placing target controls. Because we were using a traverse application with the scanner, the point cloud was registered before we left the site.

The onboard traverse app is a fantastic tool for anyone using a P-Series laser scanner as the functions help to maintain the quality of scans to site control. Significant time is saved by having registered the scans in this way. Doing the same site with a total station would have been quicker, because we would have checked the road every 10m, however, critical areas may have been missed between the 10m intervals. Because the ScanStation P30 covered the entire road nothing is missed and more time is saved in the long-term. So together with the ScanStation P30 it’s a very fast laser scanning solution.

Mapping in realistic clarity: easy to read reports

We can offer clients many types of reports using the laser scanning solution, which is a value-add for us. We use Leica Cyclone 3DR to turn our field data into final DWG. and PDF format deliverables for the client because it’s very fast to get the results in and out.

The data from the ScanStation P30 is seamlessly integrated from one software application to another because it’s already pre-registered via the traverse app on the scanner. Cyclone 3DR includes a range of adaptable and customisable tools that can be used to create different 3D deliverables and reports.

In this project, the design surface was loaded into Cyclone 3DR as well as the point cloud to generate heatmaps, as well as cross sections and deviation reports for the local council. The resulting data can then be separated by colour to isolate areas of interest and problem areas. The pavement inspection script was also used to check the smoothness. It’s easy for us and the client to read these and translate them into recommendations.

Adding 3D laser scanning to our range of services has already resulted in more business. It gives us the edge as a partner, especially in our field of civil infrastructure, where accuracy is paramount. It’s another tool in our toolbox, ideal for situations where you need high-quality 3D data to identify more valuable information and easily find areas of interest.

Nelson Boquin, Senior Surveyor

Nelson Surveys – Reality Capture Professionals, specialising in:

Laser Scanning – Topographic Surveys – As constructed Verifications – Engineering – Infrastructure.