Celebrating 10 years of the world’s first scanning total station with 5 standout cases

This year marks the 10-year anniversary of the Leica MultiStation, a world’s first innovation. Blending a compact laser scanner and highest performance total station for full data fusion was a feat that defined an entirely new product category: the scanning total station.

Since its debut, the MultiStation’s lineup of capabilities has made it an indispensable instrument on many projects. To celebrate this milestone, we are featuring five standout applications across the decade and around the world, demonstrating both the impact of the MultiStation and the amazing work of Leica Geosystems customers.

Developing a world’s first innovation

Involved in developing the MultiStation from its inception, Leica Geosystems Business Director Hans Martin Zogg reflected on the instrument’s history in an interview:

“We clearly saw the need to bring together the total station and scanning capabilities into one instrument,” he recalled. “Scanning devices at the time were huge and heavy, so it was a challenge to convert that into a small telescope with scanning capabilities.”

However, combining the hardware was only one of the hurdles.

“We also needed to make software advances to bring the scanning and total station data together into the same coordinate system and interface,” explained Zogg.

Having overcome these initial challenges, the MultiStation successfully entered and altered the market in 2013 and continues to improve with advancements like 30,000 points per second scanning speeds and seamless data integration in Leica Captivate field software with 3D visualisations, and autonomous data collection. Further improvements in automated performance included Dynamic Lock, enabling the MultiStation to detect and follow moving prisms, speeding work on dynamic sites.

Customers have used the MultiStation on a range of unique projects, showing how innovative technology and customer expertise combine to enable powerful outcomes.

#1: Scanning the Mount Blanc ice cap

Extreme elevation and unpredictable weather conditions make Mont Blanc, western Europe’s highest mountain, a daunting challenge for alpinists. In a groundbreaking 2013 initiative, a team of expert surveyors embarked on a mission to perform the first-ever 3D laser scan of the Mont Blanc ice cap using the MultiStation. As part of ongoing monitoring every two years, these expeditions provide climatologists with valuable insights into the ice cap’s variations.

Battling strong winds, freezing temperatures, and challenging terrain on their way to the summit, the team nonetheless successfully scanned the ice cap with the Leica MS50 and made accurate height measurements using GNSS. From the scan data, the team produced a point cloud of the ice cap for precise volume calculations and a 3D animation of the area.

Despite technical complexities and extreme environmental conditions, the MS50 offered a new dimension to high accuracy measuring in challenging terrains. The expedition not only demonstrated the capabilities of the cutting-edge surveying equipment, but also highlighted the convergence of individual expertise and technological advancement for capturing valuable data.

# 2: Preserving a recovered 16th-century warship

Embarking on a journey through time, the Mary Rose, King Henry VIII’s Tudor warship, holds centuries of maritime history within its timeworn hull. After a catastrophic sinking in 1545, the vessel rested on the seabed for centuries until its remarkable discovery and subsequent excavation in 1982. Fast forward to today, the Mary Rose continues to captivate enthusiasts and scholars alike as it undergoes a meticulous conservation process, aided by the MultiStation.

In a collaborative effort, the Mary Rose Trust and Leica Geosystems have integrated the Leica MS50 into the conservation plan for this historic artifact. The precision measurement capabilities of the MS50 play a crucial role in monitoring the movement and drying process of the Mary Rose’s 500-year-old timbers. Installed with optimal line-of-sight coverage and 36 reflector targets, the MultiStation measures hull movement three times a day, providing essential data to understand the effects of controlled drying on the ancient wood.

The Mary Rose fully reopened in 2016, inviting the world to share in the immersive experience of this extraordinary historical artifact. Visitors not only witness history but are also engaging with the technology that aids in the conservation of this iconic Tudor warship and safeguards cultural heritage.

#3: Enhancing NASA Space Launch System testing with the MultiStation

To advance the testing capabilities of NASA’s Space Launch System (SLS), the U.S. space agency incorporated Leica MS50 and MS60 MultiStations into structural testing at the Marshall Space Flight Centre in Huntsville, Alabama in 2016. The combination of a state-of-the-art robotic total station and scanning capabilities enabled the MS60 to provide the measurement data needed to precisely monitor deflections during the structural tests.

Rigorous testing of the SLS ensures structural integrity and the ability to withstand the formidable forces experienced during spaceflight. Conducted outdoors using specialized structural test stands, the massive core stage tanks of the SLS were subjected to conditions mimicking those encountered during launch.

One test evaluated the liquid hydrogen tank, while the other focused on the liquid oxygen tank. Over a 48-hour period, these test stands pushed, pulled, and bent the tanks, replicating the stresses of launch. To accurately monitor deflections at multiple points on the tanks, NASA used the MS60s to make highest accuracy discrete measurements and scans capturing thousands of points per second for comprehensive data collection. Captured data not only helps evaluate tested components but also contributes to the design development of NASA rockets into the future.

#4: Simulating train passage for an historic Brazilian tunnel

Operational since 1915, the historic Tunnel of Marmelos is important to transportation infrastructure in the state of Minas Gerais. However, ongoing maintenance over its lifetime, including adding structural support, has reduced the tunnel’s clearance. In 2022, Magna, experts in consulting engineering for infrastructure projects, surveyed and simulated train passage through the tunnel using a 3D model to determine if the tunnel could safely accommodate larger trains than those currently in operation.

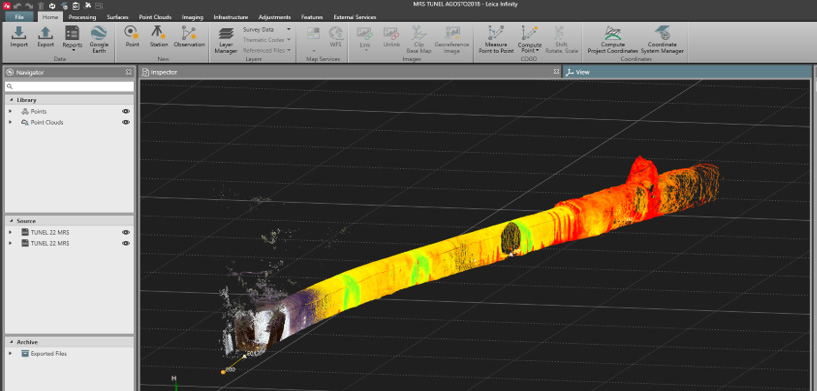

With a strategic focus on integrating advanced technology into their work, Magna captured comprehensive survey data with the Leica MS60, transformed into high-accuracy 3D simulations. The MS60 showcased its efficiency by enabling the team to successfully survey 200 metres of the tunnel and its surroundings in a single day thanks to the rapid data capture of laser scanning. By importing and processing the data in Leica Infinity software, the team easily combined total station measurements and scan data into a unified point cloud.

This data, exported into PTS format, was further processed in Leica Cyclone 3DR (formerly 3DReshaper) to create a 3D model. Magna was able to visualise and analyse different train passage scenarios section by section with the high-accuracy 3D model, delivering key information to stakeholders. Cross sections, profiles, and further deliverables were generated in the CAD system, fully integrating into Magna’s regular workflows.

Their experience revealed a significant advantage in opting for the MS60 over conventional topographic survey methods. The extremely high accuracy coupled with fast data collection and processing times made fast work of high-quality deliverables. Additionally, the collected data proved readily applicable to BIM, highlighting how the MultiStation can help firms align with modern infrastructure planning practices.

#5: Detecting reflectors in the world’s largest filled aperture radio telescope

In a remote area of China’s Guizhou province stands a technological marvel advancing our understanding of the cosmos – the Five-hundred-metre Aperture Spherical radio Telescope, better known as FAST. Built by the National Astronomical Observatory of the Chinese Academy of Sciences, FAST is not only the largest filled-aperture radio telescope in the world, but also the most sensitive. Capable of capturing radio waves from celestial objects, including previously undetectable weaker signals, FAST has already enabled a range of discoveries, including over 800 pulsars and an approximately 2-million light-years-wide atomic cloud.

While in operation, FAST’s active reflector, an important subsystem which controls and forms a parabolic surface to receive radio waves from the universe, must be closely monitored. For this important task, the National Astronomical Observatory selected the Leica MS60 MultiStation. The MS60 is used to accurately fit the reflecting surface and adjust the position of the feed cabin. This ensures the reflecting surface can actively adapt its shape according to the target position of the celestial object and achieve accurate signal reception.

Before sunrise, the team takes a first set of measurements, setting up the MS60 with a resection, determining the scanning density and distance, and collecting the data. The process is repeated before sunset with the same parameters and the acquired data is imported into Leica Cyclone 3DR software for comparative analysis of the reflectors.

In this unique case, one world’s first helps enable the continuous operation of another – detecting any changes in the reflectors with powerful, precision measurements enables FAST to continue to pushing the boundaries of radio astronomy.

Curious to learn more about the Leica MS60 MultiStation? Watch the MS60 Webinar or download the dedicated White Paper to find out how the MultiStation can improve your productivity in daily tasks and challenges.