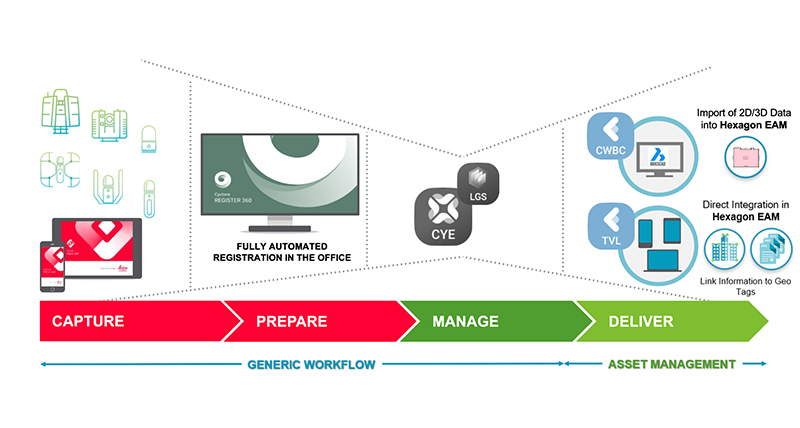

Registering for an asset management tool requires you to capture every asset individually, import them and then enter the necessary information. This task takes a lot of time to complete and can be improved with a better workflow. That is precisely the goal of Scan-to-EAM, where you can combine reality capture data with the identification of assets to import into the EAM solution database. Such a workflow would significantly increase efficiency and reduce costs as facility managers will always know the status of every asset.

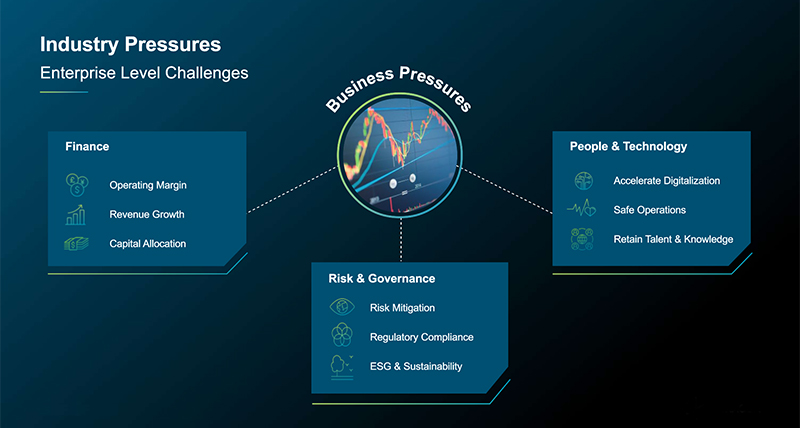

The industry and its challenges

Facility management companies are faced with multiple challenges such as financial, risk & governance and people & technology. It is no secret that if these challenges are not addressed, they can hinder a business’s ability to grow. From a financial perspective, it is often expected to cut costs and grow the revenue streams simultaneously, which is challenging but can be achieved with a solid strategy with digitalisation as a central part of optimising existing workflows.

Defining when maintenance or repairs are required is a manual task, from checking the asset to updating the information on paper. This shows that maintenance and repairs are rarely tailored to individual assets and their parts. Because of this, facility managers are often forced to order spare parts pre-emptively in bulk. Compared to optimised asset utilisation and maintenance, the costs here are higher, and the lifetime of the assets is lower.

Reality capture workflows with an EAM integration

Depending on the project, various reality capture solutions are available and can be used to meet the accuracy requirements, from highly versatile survey-grade laser scanners to handheld mobile imaging laser scanners with autonomous functionalities. During the scanning process for EAM integration, three types of data are captured:

- A 3D point cloud

- An image of the area

- GeoTags

Once captured, a digital twin will be created from the point cloud and images taken. After preparing the data, it can be exported and used for other software solutions to create deliverables. The 2D and 3D deliverables are then imported to Hexagon EAM to display the building and the status of each asset captured with GeoTags.

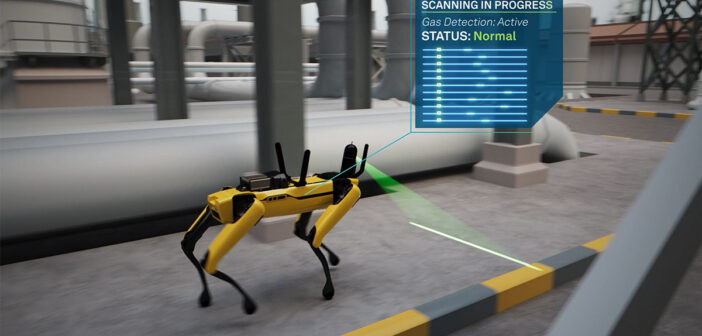

Some of these processes can be done manually, or if the environment is too dangerous for humans, they can be automated for little or no human intervention. The Leica BLK ARC laser scanning module, for example, can autonomously patrol a facility regularly to repeat scan missions and detect any differences or site changes. Once the captured data is registered, any deviations can be dealt with by the notified person. Spare parts can be produced or ordered and then replaced at the exact location the scanner identified. Such a workflow minimises the risks and time spent on site to increase efficiency and reduce maintenance costs.

Hexagon EAM – a first step towards an autonomous future

The next-generation EAM solution offers many features to increase the efficiency of maintenance workflows. Three key areas that Hexagon EAM is focusing on are:

- Work processes

- Asset performance management

- Smart Digital Reality™

Better work processes significantly impact employees’ efficiency, health, and safety as more information about the assets is available. This allows them to plan, schedule and execute maintenance tasks better and save materials with the exact details about an asset.

Once an asset is in the Hexagon EAM database, the asset performance management of the EAM is responsible for observing and maintaining it. Various concepts of condition monitoring, predictive forecasting, and reliability-centred maintenance (RCM) have a high potential to improve registered assets’ sustainability and energy consumption. Knowing when maintenance will be needed makes it easier to plan and maintain them at a lower cost.

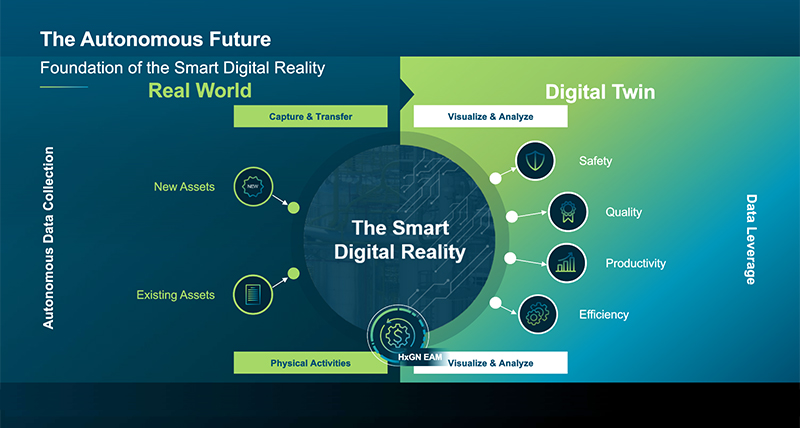

The last part of the foundation for an autonomous future is Smart Digital Reality. Hexagon’s Smart Digital Reality for industrial facilities is the intersection between the real world and the Metaverse that helps companies maintain safe and sustainable operations. To achieve the lowest practical cost and optimise plant production and worker productivity by facilitating the capture and integration of data from any source. Contextualising, visualising and facilitating work process enhancements across the entire asset lifecycle. The Smart Digital Reality consists of the building blocks of digital projects and digital assets, all enabled by the digital backbone.

Integrating Smart Digital Reality into Hexagon EAM

Hexagon EAM sits at the intersection to connect the physical with the digital world, the Smart Digital Reality. While digital projects look at the as-built, digital assets look at the as-maintained side to cover the entire asset lifecycle. The digital backbone is the facilitator to ensure interoperability and that all data sources are captured and applied in context. Companies can leverage autonomous data collection of field data and enable technicians to validate data points to ensure the full picture is captured in the real world.

The registered assets are not just merely a virtual representation but are infused with intelligence that comes from manual or autonomous updates created by IoT devices, laser scanners, or flying laser scanners. That is one part of automating processes and analytics to slowly remove human intervention on the journey to a fully autonomous future. Hexagon EAM leverages the captured data using its Smart Digital Reality Intelligence Engine to help users plan and execute repairs or replacements of specific parts or an entire asset.

With a complete asset lifecycle management, maintenance and financial planning, the Smart Digital Reality intersection enables a continuous feedback loop to understand the enterprise holistically. Better visibility into mission-critical assets based on the collected data from the real world allow you to make evidence-based and actionable decisions. Because of that, safety, quality, efficiency, and productivity are improved, contributing to economic and environmental sustainability.

The potential of Reality Capture and EAM in the future

Every business relies on its assets. They are in every part of operations and essential for success. To achieve operational excellence, a fully autonomous future with a continuous feedback loop between the Smart Digital Reality and Hexagon’s EAM is required. Asset management is the cornerstone of operational excellence. It allows companies and their workforce to operate on a higher level of productivity, ensures that regulatory constraints and obligations are met, and helps optimise budgets. A digitised asset management strategy provides higher organisational visibility, increased enterprise reliability and operational efficiencies. Hexagon EAM can be leveraged across many key business areas, providing a comprehensive picture of the current state of operations and insights into what issues need to be addressed.

Hexagon EAM can manage any physical assets; once registered it can support many business processes. When the assets and processes are defined, Hexagon EAM can support various maintenance strategies to align with what best fits your company today while ensuring you can mature over time. With all this in place, business decisions can be managed through next-generation EAM technologies to automate decision-making and improve outcomes. All of which enables true enterprise-level business objectives, taking your digital transformation journey to the next level.

The benefits Scan-to-EAM offers

There are many benefits to profit from when looking at the capabilities of Hexagon EAM. You save time during registration and maintenance as assets can be easily imported and later located with the geo-tagging function. The detailed information on the assets is also easier to access in the field to see their status. More accurate information about the individual assets helps to plan maintenance or repairs and determine if spare parts need to be produced or ordered. This lowers the cost of maintenance and repairs as these are only done when necessary and no longer pre-emptively.

This helps the facility managers coordinate their work better and makes it more autonomous with the available technology. With more autonomy, the safety of workers increases as their presence, in hazardous environments, is reduced to a minimum. But it requires continuous training of the facility managers to continuously improve their skills in operating the hardware and software solutions.

Financial benefits can be seen with a higher degree of automation which reduces human intervention. Intelligent software solutions increase productivity in the office with automating the registration process, and as fewer deliverables are required for Hexagon EAM, less time is needed to create them. The adaptation of Hexagon EAM allows you to increase productivity, autonomy, and safety while reducing costs.

Jesus Bonet

Director Sales and Business Development

Terrestrial Laser Scanning

Hexagon Geosystems Reality Capture Division

Kevin Price

Vice President Portfolio Strategy and Enablement

Hexagon