In September 2022, the Leica Geosystems GIS Collectors team sent one of their interns, Macdonagh Dressler, to walk 330 kilometres, rain or shine, around farm fields in Heerbrugg, Switzerland.

What was the purpose of this long-distance errand, why did he agree, and what was ultimately accomplished?

Dressler’s high-mileage efforts were all in the service of testing and validating the precision of Leica Geosystems GNSS equipment commonly used to verify farmland area ownership claims within the European Union. In this blog, Dressler shares technical details of the work, his experience in the field, and the significance of the project.

GNSS Certification in the EU

The European Union Common Agricultural Policy (CAP), created to support the agriculture industry, offers subsidies to farmers based on several factors, including the amount of land they farm. To receive funding, farmers submit their information and member states perform on-the-spot inspections each year using GNSS equipment to verify their claims.

The equipment must have its precision verified through a rigorous certification process required by the European Commission’s Joint Research Centre (JRC). Therefore, it is a priority for the GIS Collectors team to obtain certifications for their GNSS smart antennas, the Leica Zeno FLX100 plus and the Leica Zeno GG04 plus.

“We certify our hardware in many different configurations, giving a range of options to our customers,” says Dressler.

Configurations differ by the types of GNNS corrections, satellite frequency bands, and data controllers used, and only certified configurations are valid for customer use. This year, the Zeno team certified:

- The FLX100 plus using multi-frequency and dual frequency (L1/L2) bands and HxGN SmartNet RTK corrections, with the Leica Zeno Tab 2 controller

- The GG04 plus using only L1 bands and Satellite-Based Augmentation System (SBAS) corrections, with a Leica CS35 controller tablet

Redefining field work: GNSS testing across farmland

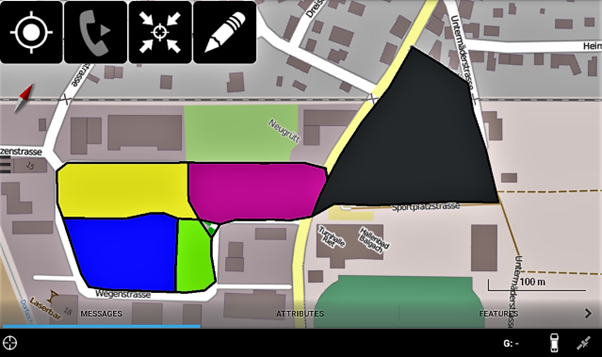

The testing to achieve certification is demanding and, to pass the CAP inspection, precision is important as measurements must be repeatable across times of day and weather conditions. To collect the data needed to certify instrument precision, Dressler conducted testing across six parcels of land. These parcels ranged in area and shape and contained variations of open sky and semi-urban conditions.

“For each test, I measured 36 rounds of each parcel over ten days. I alternated clockwise and counterclockwise, along with the time of day, making sure to vary the measurement conditions,” explains Dressler.

In the first certification test, Dressler used the compact FLX100 plus mounted on a survey pole for highest accuracy. Paired with the Zeno Tab 2 and integrated Zeno Mobile software, data collection, visualisation, and all-weather operation were made easier.

“When it was raining, I set an auxiliary button on the Zeno Tab 2 so I wouldn’t need to touch the screen. Additionally, the long battery life of both the smart antenna and tablet meant I could stay in the field all day without any worries,” recalls Dressler.

Further supporting accuracy, this configuration included HxGN SmartNet RTK corrections based on positioning data from the largest global reference station network. This configuration gave him consistent 2cm-accuracy and allowed him to take measurements reliably, even next to buildings and trees.

In the second certification test, Dressler used the GG04 plus smart antenna with SBAS corrections, and only L1 frequency bands.

“In this test, I used five second averaging to try and increase the precision,” details Dressler. “Additionally, using the CS35 Windows tablet with Zeno Connect and ArcGIS Collector, I streamed my data to colleagues in the office in real time.”

Removable batteries in the GG04 plus let him easily change out his power source in the field, extending working times. Zeno Connect automatically reconnected so there were no delays in data transfer.

Results: 330 kilometres, 10,000 points, and 2 certifications

Conducted over the month of September in a range of weather conditions, Dressler walked over 330 kilometres, measured 10,000 points, and listened to three full podcast series and four audiobooks.

“Completing the certification for the FLX100 plus with Class 5 recognition was a huge achievement. This meant that the buffer width was less than 0.5m” says Dressler. “Using the skills I developed performing the first test, I was able to achieve Class 4 recognition with the GG04 plus.”

“These certifications allow our customers to use our hardware to perform CAP inspections, expanding their uses throughout Europe.”

“The JRC certification process was gruelling, but rewarding,” reflects Dressler. “I did it to make sure our customers would not be restricted in their uses of our antennas, especially for important objectives like getting funding to farmers.”

Find more information about Leica Geosystems Smart Antennas here.