Reality capture technology has rapidly advanced over the last two decades and, in the process, transformed the surveying industry. Using 3D laser scanners, surveyors can now capture data from millions of points per second to create colour point clouds representing a digital twin of the physical world. These point clouds form the foundation for 3D models that clients in many industries, like building construction, facilities management, infrastructure and more, require to carry out their work.

Coenradie, a surveying firm in the Netherlands, has over 20 years of experience using 3D laser scanning to capture precise measurement data for their clients. As early adopters who have consistently invested in new laser scanning hardware and software, they have a unique overview of the role and impact of this technology on the industry.

This blog reviews insights delivered by Coenradie’s Innovations Manager, Sander Schröder, during a presentation at the online 2021 FIG Conference. Schröder uses experiences and historical data from the company to provide insights into how developments in 3D laser scanning are shaping surveying services today. He also makes forecasts for the future and offers recommendations to help surveyors prepare for industry shifts and thrive in business with reality capture technologies.

Then and now: 3D laser scanning hardware and software

Schröder recalls the early days of laser scanning when surveyors had to choose between pulse-based scanners, which offered long-range, high accuracy scans, or phase-based scanners, which enabled short-range, ultra-high-speed scanning.

In contrast, today’s waveform laser scanners provide the best of both worlds, combining LiDAR, positioning technology and 360-degree cameras to deliver data-rich, colour point clouds quickly and with high accuracy. The current Coenradie laser scanning line-up includes the Leica ScanStation P50, the Leica RTC360 and the Leica BLK2GO. Schröder says these instruments allow his business to collect more data faster than ever before.

“Higher scan speeds allows us to gather more information,” explains Schröder, “and with the lighter scanners, our surveyors can do more setups to increase the resolution and capture everything.”

From the limited 2D CAD and plant drawing software options available in 2000 to the crowded field of sophisticated 3D modelling software currently on the market, Schröder has seen large strides in software designed to work with captured data. Coenradie invests in a range of laser scanning software, including Leica Cyclone FIELD 360, Leica Cyclone 3DR, Leica CloudWorx CAD plugins and more, to complete point cloud registration and deliver intelligent modelling services for clients.

Decreasing costs of laser scanning

Decreasing costs of laser scanning

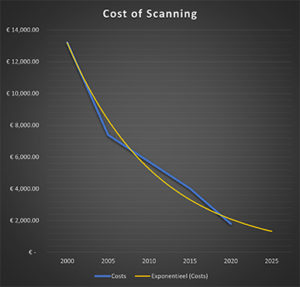

While these developments have increased capabilities, they have also decreased the total costs of laser scanning services. Schröder demonstrates this by presenting scanning costs across a historical time frame to reveal a drastic decline.

His calculations use specifications from a 2020 project in which Coenradie provided laser scanning and 3D modelling services to support an urban residential renovation. Factoring in prior generations of equipment, the required number of scans and working hours, he calculated the project’s costs at different points along the technology timeline.

Using 2000 as a baseline, Schröder found a 56.8% decrease in laser scanning costs from 2000 to 2010 and an even more dramatic drop of 86.4% by 2020.

“Based on these calculations,” predicts Schröder, “we expect to offer that same project in 2025 for only 11.4% of the original scanning costs.”

At the same time, his calculations show more comprehensive outputs in faster times, including reduced minutes per scan setup from 22.5 in 2000 to just 3.5 in 2020, with more scans per project. Overall project scanning hours decreased from 52 in 2000 to 6.5 in 2020, while deliverable offerings, like 3D models with complete image colouring, increased.

“The cost of laser scanning has gone down dramatically in the last twenty years,” Schröder concludes. “While it might not decline with such large steps in the future, it will definitely continue to go down, especially if the accuracy of instruments like the BLK2GO become sufficient for these types of projects.”

5-year forecast: preparing for the future

5-year forecast: preparing for the future

While lower costs and easy-to-use 3D laser scanning technology currently provide a great return on investment for surveying service providers, these features also signal wider accessibility of reality capture technology outside the surveying industry. Schröder explains that this will cause shifts in the services clients seek and the specialisations surveyors should prepare to offer.

Schröder predicts that more clients will invest in 3D laser scanning technology over the next five years and complete their own data captures.

“With the BLK2GO, there is one button to start scanning,” says Schröder. “We walk where we want to go, and we stop the scan with the same button. The ease of scanning makes it great for people to perform laser scanning themselves.”

Additionally, he expects more clients to perform their own final modelling: “In the past as a service provider, we always had to deliver a model because our clients typically could not work with a point cloud. But now, some clients work with Cloudworx or Autodesk ReCap, making the model as a deliverable optional.”

Although laser scanning and modelling will continue to comprise part of service providers’ offerings, Schröder does not recommend relying on these exclusively. Instead, surveyors can use the following strategies to prepare for the future:

1. Offer flexible service combinations to meet a mix of client needs

As more clients in multiple industries begin to own reality capture technologies, adapt offerings to areas where advanced surveying expertise is needed most. Be ready to offer more choices and configurations of services based on the client’s resources and deficits and actively look for ways to add value.

2. Invest in software to provide advanced services

Schröder predicts that clients will continue to need many of the advanced processing and post-processing services surveyors can offer – and software is key to these services. Continuously investing in and updating your services with state-of-the-art software capabilities will provide a competitive advantage in the future.

For example, Coenradie uses Leica Cyclone to offer clients automatic extraction services and uses modelling software like the CloudWorx for Revit plugin to quickly create advanced and intelligent building models, bringing value to customers in terms of time and quality.

3. Focus on quality control and quality assurance

With more cloud-to-cloud registration taking place in the field, Schröder notes that there are gaps in traditional surveying ground control – gaps they can address through quality control and quality assurance services. When more clients perform their own scanning and modelling, the expertise to provide accuracy checks of models against the as-is point cloud creates significant value.

“It is a really challenging task to go through a complete point cloud from corner to corner, from detail to detail, to see if the point cloud and the model match correctly,” explains Schröder. “With Cyclone 3DR, we are able to quickly see if there are deviations out of tolerance or specifications where the model needs to be changed.”

Sander Schröder

Sander Schröder

Manager Innovations

Coenradie – World-class Surveying Solutions

To learn more about how Leica Geosystems can help you to grow your business with 3D laser scanning, visit our Pure Surveying website.

Read further blogs to learn how other organisations are growing their business with 3D laser scanning.