When you think about 3D laser scanning, you may think of documenting large-scale buildings, plants or facilities. But it can also be used to tackle extremely technical engineering challenges.

The millions of data points gathered from 3D laser scanning can be used to create information-rich deliverables to expedite analysis and prefabrication. TruePoint’s engineering team brings clarity and resolution to advanced engineering projects, helping clients plan more thoroughly for upcoming work.

Expediting the Installation of ACM Panels

Expediting the Installation of ACM Panels

A client working with LaGuardia Airport was installing ACM panels to the canopy of a newly constructed terminal. The construction plans did not match the existing conditions at the site. A deviation could cause a significant setback; the installation process needed to be precisely planned to avoid rework. We 3D laser scanned the canopy and curtain wall façade with the Leica ScanStation P50 to capture true as-built data and generate 2D drawings and a 3D model to prefabricate panels and expedite installation.

Our client was working overhead in a lift 80 feet in the air, and there was no room for trial and error. They were not interested in hanging panels, discovering issues and having to take them back down. We have worked on several projects with this client, so they understood the value of 3D laser scanning.

Engineering Solutions for a Power Stack

Engineering Solutions for a Power Stack

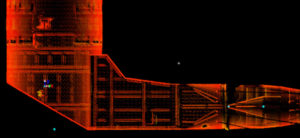

One of Georgia’s largest power supply cooperatives requested our expertise for one of its power stacks. The client wanted to verify all brackets were correctly aligned before installing baffles and determine if the guides needed to be moved to accommodate for thermal growth.

The power stack was 3D laser scanned with the Leica ScanStation P50 and the Leica RTC360 3D laser scanner. Our engineering team delivered intensity map point cloud files, 2D drawings and an AutoCAD Revit LOD 200 model. These deliverables were used to help define design repairs.

Installing Large-Scale Exterior Signage

Installing Large-Scale Exterior Signage

A new construction sports stadium was installing large-scale exterior signage. Our client (specialising in the design, fabrication, and installation of signage) needed to verify the centerlines of the structural steel framework where the components would be fitted to.

We 3D laser scanned the project site with the ScanStation P50. The value of our services was recognised almost immediately on this project. Upon reviewing the data TruePoint provided, the client noticed that the steel on the north and south ends of the stadium did not align with the design plans. As a result, our client and the project’s general contractor made arrangements for the steel in these areas to be corrected.

Our experienced team works with each client to understand their project scope and provide innovative engineering solutions. We utilise best-in-class technology from market leaders such as Leica Geosystems and Autodesk to deliver incredible data with trouble-free integration. Our solutions improve productivity and expedite fieldwork, thereby reducing change orders, delays and costs.

Ryan Hacker, President

TruePoint Laser Scanning

Click here for more information on TruePoint Laser Scanning

Visit Leica Geosystems website for more information about 3D laser scanning solutions and further reading on our Blog