The goal behind every measurement and 3D model is to provide actionable information to make informed decisions to plan, construct and maintain the infrastructure around us. When surveyors are geared with a comprehensive fleet of equipment, they can extract more information and undertake bigger and more complex projects.

This blog explores six outstanding projects in innovation, scale and complexity.

Inspecting dams for sustainable hydropower

Surveying UAVs change the geospatial industry and offer enormous potentials for surveyors. Axpo uses the Aibot for the inspection of several active dams and for other indoor and outdoor surveying projects.

One of the hydroelectric dams surveyed by Axpo is Lai da Nalps, a massive structure of 127 metres height and 480 metres in Tujetsch, Grisons, Switzerland. Axpo’s inhouse team of surveyors, trained to use Leica Aibot for surveying tasks, inspected the dam to document the condition for the long-term understanding of the dam’s health.

Even with precise planning and the perfect locations, the previous methods the team used to inspect the dam were very time-consuming, sometimes even dangerous, and couldn’t deliver as highly detailed images and quality results as the ones taken with a UAV facing the dam from an approximate 10 m distance.

Even with precise planning and the perfect locations, the previous methods the team used to inspect the dam were very time-consuming, sometimes even dangerous, and couldn’t deliver as highly detailed images and quality results as the ones taken with a UAV facing the dam from an approximate 10 m distance.

The inspection of a large dam takes two to three days and approximately 10 hours of total flight time. During the flight, the Aibot takes automatic images every two seconds, enabling the pilot to focus just on flying the copter at a constant height and distance close to the wall.

“Using a UAV has widened our toolbox of available equipment technologies we can use for our daily tasks. Total stations, GNSS rovers and smaller UAVs are as common tools for us as it is the Leica Aibot,” said Thorsten Zimmer, engineering surveyor at Axpo, responsible for the inspection project in Lai da Nalps.

Read all the uses Axpo is giving to its Leica Aibot in this case study.

Where is the line? Augmented perception of utilities with AR and GNSS

vorarlberg netz distributes electricity and natural gas through a network of 10,794.6 kilometres of overhead lines and underground cables and more than 2,000 kilometres of natural gas pipeline systems. Digitally visualising georeferenced utilities in 3D allows vorarlberg netz field staff to intuitively experience in real-time the underground supply infrastructure and enhance natural environments via smart devices.

vorarlberg netz is using state-of-the-art Augmented Reality (AR) and GNSS to make the task of restoring lines easier. AR technology superimposes digital information on an environment providing actionable information to solve problems or a specific task. Combined with GNSS, users can visualise and position utilities with survey-grade accuracy.

“The use of modern BIM technologies in our company requires, in addition to the planning of new objects, the collection of inventory data using a laser scanner. In combination with 3D GIS data, this opens up new possibilities in the area of facility management and the visualisation of the digital twin with Augmented Reality,” says Andreas Mätzler, head of geoinformatics at vorarlberg netz.

Discover voralberg’s applications and benefits from using AR with GNSS for utilities.

Monitoring the construction of London’s second tallest building

City landmarks are not built overnight. In between planning, design and construction, there are other crucial activities – just like monitoring and positioning – happening at the same time.

22 Bishopsgate, London’s second tallest building, rose through the air in the United Kingdom with the help of Leica Geosystems monitoring systems. Accurate and reliable positioning on the status of structures displayed as actionable data is crucial to make fast and informed decisions and react to potential problems.

After each jump, or elevation of the rig to build a new level, the Careys Civil Engineering surveying team needed reliable coordinates to proceed setting out the structure and to verify the correct positioning of the core. The main task of the automated positioning system Leica Geosystems created is to obtain precise and reliable coordinates during the entire construction process that are not influenced by the movement of the building.

Leica Geosystems developed a procedure, using GNSS observations combined with tiltmeters (precision inclination sensors), to obtain reliable coordinated points at the top of the formwork of the ascending skyscraper. Those coordinated points, or Active Control Points (ACP), were sighted by Leica Geosystems robotic total stations to setup its coordinates and orientation.

“The Leica Geosystems solution allowed for a fully-automated workflow and computation of the results and fast delivery of coordinates when required, optimising costs and time of operation for the surveying team compared to different methodologies,” said Damien Watson, senior engineer at Careys Civil Engineering, Plant and Fleet department.

Transforming Ayacucho into a digital city

Digital cities initiatives aim to collect valuable data and capture all surroundings in urban settings to generate smart models, supporting decision making processes and facilitating the delivery of new urban services. The mobile mapping, reality capture, airborne and asset management solutions provided by Hexagon are used in cities around the globe, helping to digitise urban centres.

Aware that 3D models help to inform the perception on reality and provide a georeferenced digital base for operations in a city, Patronato Pikimachay, a non-profit organisation, approached C95 Creative, a leading global architecture and design firm, to create a smart digital city model of Ayacucho, Peru.

Aware that 3D models help to inform the perception on reality and provide a georeferenced digital base for operations in a city, Patronato Pikimachay, a non-profit organisation, approached C95 Creative, a leading global architecture and design firm, to create a smart digital city model of Ayacucho, Peru.

To undertake a precise digital survey that would be the basis for a digital city model, the project collected georeferenced point clouds with images from 150 blocks in Ayacucho’s historic centre. Using a combination of Geosystems solutions, data from a 50-kilometre trajectory was collected in three days and the entire project deliverables were completed in six months.

“A valuable database for smart cities is essential during the decision making of future urban interventions. We have been able to generate databases of great value for cultural heritage, cataloguing, restoration and refurbishment works. We will keep exploring and looking for new ways of applying this technology in our sector with Leica Geosystems,” said Irene Ibisate, architect and director for the smart city Ayacucho project at C95 Creative.

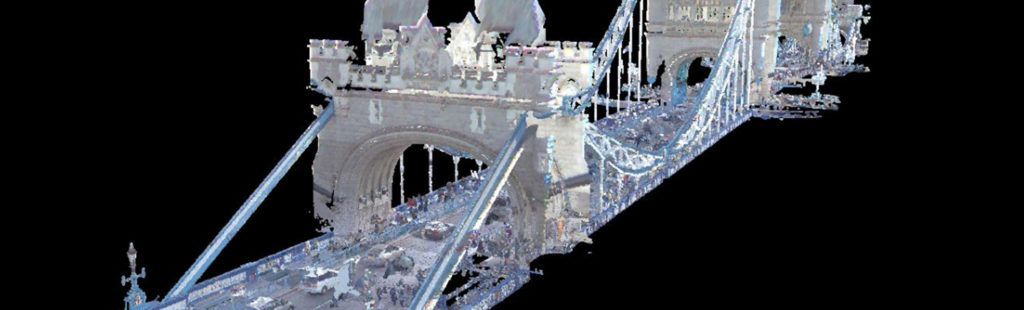

Documenting London’s boroughs to solve parking problem

Cities across the world keep struggling with the problem with wasted fuel, and emissions adding up to the economic and non-economic impact of parking hunting.

AppyParking, a London-based kerbside management and mobility technology firm, operates an award-winning parking app, helping users make informed choices about where to park before they arrive.

AppyParking needed to survey London’s kerbsides to create an accurate map of all parking zones across the capital. The parking company approached Getmapping Plc, a leading provider of aerial photography, mobile mapping, LiDAR, digital mapping to undertake mobile mapping surveys of car parking zones across London.

Geared with two Leica Pegasus:Two Ultimate mobile mapping systems, Getmapping undertook the largest mobile mapping project in Europe. A team of three surveyors drove 25 kilometres per day with the Leica Pegasus:Two around London’s boroughs to simultaneously collect imagery and LiDAR data. Surveying was possible throughout winter months of poor light, and no surveyors or traffic management crews were needed in the road.

Geared with two Leica Pegasus:Two Ultimate mobile mapping systems, Getmapping undertook the largest mobile mapping project in Europe. A team of three surveyors drove 25 kilometres per day with the Leica Pegasus:Two around London’s boroughs to simultaneously collect imagery and LiDAR data. Surveying was possible throughout winter months of poor light, and no surveyors or traffic management crews were needed in the road.

“The progress of surveying methods and mobile mapping systems opens new perspectives for the collection of road data. With the Leica Pegasus:Two Ultimate we were able to smoothly collect data, travelling around the survey sites around London, with no traffic management or road closures required,” said Martin Tocher, group innovation director at Getmaping.

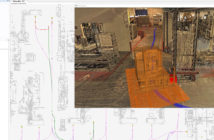

Revolutionising Smart Factories with reality capture

Digital copies of the physical world are one of the key elements of a Smart Factory. To manage and monitor physical processes in an autonomous decentralised way, numerous technologies need to be orchestrated within copies of the physical world.

Elettric80, a leading company specialised in the implementation of flexible and modular integrated automation solutions for high-volume consumer products manufacturers, uses 3D reality capture to design modern automated warehouses. This Italian company has installed more than 2,000 automatic systems all around the world.

To design and build effective and safe factories designed according to the manufacturer’s application needs, Elettric80 experts digitalise each plant before design and development. Using a combination of Leica Geosystems’ laser scanners and a total station, experts can produce various deliverables, including 2D layouts, 3D meshes and models.

To design and build effective and safe factories designed according to the manufacturer’s application needs, Elettric80 experts digitalise each plant before design and development. Using a combination of Leica Geosystems’ laser scanners and a total station, experts can produce various deliverables, including 2D layouts, 3D meshes and models.

Having a complete 3D model of a warehouse has helped Elettric80 to improve operational efficiency through optimisation of design, production routes, management of maintenance and positioning of machines.

“We adopted a novel workflow for the design of automated warehouses that improved the traditional development process by performing a 3D survey that combines terrestrial laser scanners and a total station. Then extracted high-level information about the environment, exploiting innovative algorithms for large-scale point cloud processing,” said Mikhail Giorgini, R&D project leader at Elettric80.

Get inspired to grow your surveying business

By Renata Barradas, Communications Manager at Hexagon Geosystems