The aim of Industry 4.0 is to comprehensively digitalise industrial production to better equip it for the future. Modern information and communication technology and intelligent, digitally networked systems are interlinked. With their help, largely self-organised production is made possible: people, machines, plants, logistics, and products communicate and cooperate directly with each other in Industry 4.0. Networking no longer optimises just one production step but an entire value chain. This picture can be transferred and applied to the construction industry. Such a networked process encompasses all phases of the construction life cycle – from the idea of a construction project to development, production, use and maintenance to demolition. We look at the challenges and opportunities digitalisation poses for the construction industry with Armin Kamenschek, PhD student at the Vienna University of Technology, and Stefan Beer, Solution Architect at the Rhomberg Group.

Armin Kamenschek, Project Manager, New Construction Technology Department, at Österreichisches Siedlungswerk (ÖSW)

Mr Kamenschek, would you briefly introduce yourself to us?

My name is Armin Kamenschek. I was born in South Tyrol and live and work with my family in Vienna. I am a trained carpenter but have completed architecture, civil engineering and political science courses at various universities. Nevertheless, I have remained loyal to the Vienna University of Technology. I am currently completing my dissertation at the Technical University of Vienna, in parallel to my employment as a project manager in the Technology Department of the ÖSW company – group.

Please give us an overview of the type of projects you are working on.

My professional life is divided into two parts. First, as a project manager in the construction industry with the property developer ÖSW, I oversee building construction projects in the New Construction Engineering Department with responsibility for planning, execution and BH-ÖBA agendas (client and local construction supervision). As a result, I have been intensively involved with optimising processes and the digitalisation of these areas throughout the entire life cycle. Synergies have arisen from my work as a construction project manager and from my dissertation, where I have already developed several things in this regard as part of the doctoral thesis.

The task and goal of the dissertation is to research possibilities for implementing RFID (Radio Frequency Identification) in the construction industry for approximately three to four years (2018-2022) and to implement these based on an RFID room book (definition and specification of qualities such as floor, wall, ceiling, as well as heating, cooling, ventilation, sanitary, electrical, miscellaneous) for building construction, including a life cycle consideration. RFID technology offers the possibility of automatically identifying and locating materials, machines, people and objects. Data can be transmitted contactless and without visual contact between a data carrier attached to the object to be identified and a recording unit.

As part of the doctoral thesis, an RFID prototype is being built in which the “tagging” of rooms, and subsequently of details such as floors, walls, ceilings and additional attributes, is possible via a mobile phone. This way “just in time” target/actual comparisons (Q/S-C-T: quality/scope, cost, time (in the sense of project management)) are enabled on the construction site. For further consideration on the topic of digitalisation for construction sites, the areas of BIM and robotics are linked and integrated with the RFID in construction using the example of a robot dog (on the ground) and a drone (in the air).

Dissertation Armin Kamenschek, RFID in Construction – Brainstorming Collage, © AKAM

From a scientific point of view, how do you see the changes and challenges in the construction industry in an age in which digitalisation is increasingly making inroads here?

The digital transformation, especially concerning the construction industry, requires a radical rethinking of the traditional business models that have existed or been practised up to now and holds great potential for development. We are already in the midst of the 4th industrial revolution, the age of Industry 4.0. We must use all the means at our disposal to ensure that we make the leap onto the ever-faster digitalisation train in construction and do not miss it. It is essential to consider the entire life cycle of a building object – the individual but interrelated phases of a building project: planning, building, operating, demolishing. So even if digitisation is revolutionising the construction phase itself, all upstream and downstream phases are part of the big picture in the age of digitisation. The processes taking place in them and the underlying data management are also affected.

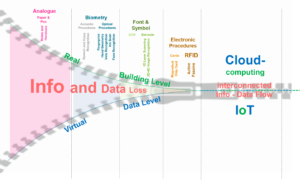

Dissertation Armin Kamenschek: Representation of info-data loss of analogue vs digital methods (Auto-ID) , © AKAM

The challenges here are the analogue interfaces that unfortunately still largely prevail in the construction industry and the associated loss of information at these interfaces. These hinder a clean and continuous data, communication, and documentation structure regarding planning, quality, deadlines, and cost management and slow down the possible technological progress in terms of digitalisation. Think about how many different parties are involved in a construction project and how selectively and partially on 2D plans or in repeatedly recreated overviews the data and information transfer still takes place. Instead all parties could have access to the same documented information and this, in the best case, over the entire life cycle of the object. This hurdle must be overcome as quickly as possible.

What aspects do you think will support and drive the digitalisation journey?

The “digital construction site” is a sub-area of the digital construction project and consists of 3D modelling, central data management, simulation of construction processes and logistics. The term “digital construction project” is considered synonymous with life cycle considerations. There is potential for development in construction in many areas; for example, through:

- Use of new technologies such as 3D or BIM planning – check model vs reality, collision planning of the trades directly on the model, cloud computing, 3D printing, VR and AR, IoT, Big Data

- Standardisation regarding data exchange between project participants, e.g. IFC buildingSMART

- Use of auto-ID systems (e.g. RFID) for contactless networking of data, machines, material and personnel, and seamless recording of material characteristics, just-in-time delivery and optimisation of construction logistics

- Refined measurement technology and sensors such as the Leica Geosystems 3D laser scanner portfolio and optimised downstream software processes and workflows support and simplify the TARGET (planning) – ACTUAL (measured building) comparison in the sense of a building shell measurement

- Automated standard processes (e.g. data management, documentation, measurement, and billing, freeing up staff for other activities) and facilitated controlling (Q/S-C-T)

- Expansion and intensification of information and communication systems (ICT)

- Use of project platforms and database systems, virtual project rooms, document management systems (DMS) or product data management systems (PDM)

- Process optimisation within the value chain/life cycle and the associated growth increase efficiency and cost savings

- Robotics in construction:

– The use of drones and robots such as the robot dog supports construction management by programmatically reading RFID tags and automating surveying activities and documentation creation, allowing skilled workers to devote their attention to more complex issues

– Exoskeletons that support people on construction sites when carrying heavy loads

It is vital that the innovations support and facilitate the workflow, not hinder, or complicate it. Digital tools such as robotic machines will replace workforce in some areas in the future. This does not mean that the human worker on the construction site will lose their job to a machine. Instead, it means that the machine will take certain tasks off the human’s hands, they will only have to control them, and the time freed up will be available for other activities and functions.

How do you see the role of Building Information Modelling (BIM) in this complex environment?

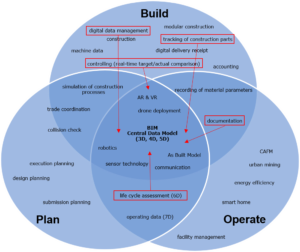

BIM models take on the task of a central, supporting data model and is seen by many as a solution and essential in a “digital construction project”. However, I go one step further. Based on my experience, I consider BIM to be important but not the most important thing. There are other processes such as:

- Digital data management and controlling (target-actual comparison)

- Tracking of components (e.g. RFID) in the construction phase and documentation in the construction-operate phase

- Documentation in the construction-operation phase, and

- Life cycle assessment (6D) in the design-build-operate phases

Dissertation Armin Kamenschek: Digital Construction Project: Plan, Build, Operate

These processes share a central place with BIM in the sense of 3D modelling and depositing additional information on the component through the application of attributes and mapping of time (4D) and costs (5D). I consider digital data management in the form of cloud computing and processes such as virtual project rooms, document management systems (DMS) or product data management systems (PDM) and information and communication platforms to be even more relevant in terms of the digital revolution in construction.

What contribution do laser scanning sensors combined with robotics and UAVs make in connection with digitalisation?

From a surveying perspective, UAVs equipped with a scanning sensor can be used, for example, to create an accurate terrain survey (as a georeferenced point cloud) in the run-up to a construction project, which then serves as the basis for the design and can be imported into the model. Likewise, can document external construction progress for terrestrial laser scanners at hard-to-reach areas based on terrain conditions.

Likewise, terrestrial robots equipped with Leica Geosystems 3D laser scanners or other measurement technology instruments can support surveying on the ground and take over recurring standardised measurement tasks, thereby automating processes and freeing specialists’ time for other tasks. Moreover, such robotic carriers can also take over these tasks especially in dangerous environments such as buildings and structures at risk of collapse or radioactive, hard-to-reach environments and thus greatly influence the safety of the specialists. However, humans are still in demand because they must monitor and support all the workflows and processes, even if this means they are relieved of some of the work.

Stefan Beer, Solution Architect in the Innovation Team of the Rhomberg Group

Mr Beer, you work at the Rhomberg Group in the Innovation group as a Solution Architect, responsible for innovations. Can you give us a brief overview of yourself and the types of projects you work on?

My name is Stefan Beer. I grew up in the Bregenzerwald and live in Lustenau with my wife and son. I graduated from the Höhere Technische Bundeslehr- und Versuchsanstalt (HTL) for mechanical engineering and automation technology in Bregenz, Austria, and studied and graduated in technical computer science at the FH Mittweida part-time. Over the past 20 years, I have worked in product development as a software developer, project manager and development manager. Since 2018, I have been working as a Solution Architect in the Innovation group service at Rhomberg. Here I am responsible for projects that revolve around new technologies and applications, help advance digitalisation in our company, and open up new business areas. Some projects, for example, deal with the topic of AI (artificial intelligence), which means that we are already using machine learning today to simplify and improve processes, among other things.

Where do you see the challenges for digitalisation in the construction industry?

The biggest challenge is the consistent digitalisation of the entire process chain. Currently, the processes are only partially digital; a lot is still done on paper. Furthermore, the data in companies and, of course, across company borders, are scattered in different systems or data islands, between which standardised interfaces are lacking. This often makes it difficult to exchange data and involves a lot of effort. Finally, there is also a lack of functioning applications that optimally support the entire process chain.

The expansion or development of the basic IT infrastructure is essential and extends to every area. Also, to the construction site. The implementation is cost-intensive and requires well-trained employees. They are the most important factor and must be taken along and accompanied during the introduction and operation of the new digital systems. This is where you sometimes encounter resistance, which is often due to fears. Patience is needed: the added value usually does not become apparent immediately with the introduction, but only over time, when more and more data is available through regular use. Therefore, the first step is to communicate the sense of purpose, accompanied by education and training of staff to cope with the change.

Based on your practical experience, when you look at the changes described by Mr Kamenschek, what does that mean for construction projects in a construction company of your size?

In a construction project, many project participants are involved throughout the entire process: customers, suppliers, service providers, and authorities. As described, the degree of digitalisation and the digital systems are unfortunately very different in some cases. Therefore, the most significant challenges are undoubtedly the additional work and the risk of lost or incorrectly recorded information.

Nevertheless, we can already see the advantages in some areas, an excellent example is planning in 3D, which allows problems such as collisions of components to be detected and rectified at an early stage in the planning. It is also impressive that a detailed survey of terrain and buildings is possible in a short time using 3D laser scanners.

UAV-generated object data transformed into a 3D model by the Rhomberg Group

For what purpose do you use BIM, robot dogs or UAVs at Rhomberg?

To put it very prosaically: To make the work easier, more comfortable, safer and more effective. For example, we use UAVs to take inventory at our Rheintal Resource Centre in Hohenems to determine the quantities of different raw materials such as gravel and crushed stone. They are also used for documentation purposes on construction sites and in existing buildings in need of renovation or conversion, such as thermal images.

Robot dogs like our Spot “Terence”, who has been part of our team since August 2020, have great potential for repetitive work and in rough terrain. For example, Spot overtakes the carrying of heavy objects or missions in dangerous environments. This is where Spot has the most significant benefit for us. By the way, it becomes really interesting with the various extensions, so-called “payloads” such as 3D laser scanners, for example, the Leica RTC360 or the Leica BLK2GO, other sensors or cameras. At the moment, we are still in the test phase to see what will be possible on our construction sites.

For the BIM topic, we have established a specialised team with Integral Planning. This team models and plans buildings in 3D and develops the planning for all trades step by step. Through the data generated in this way, we see the potential with BIM to better optimise the buildings and the associated processes to contribute towards sustainability. For example, through a more resource-efficient use of materials and machines.

Terence at work with Leica RTC360 3D Laser Scanner

What are the requirements for you resulting from the changes in the cooperation with service providers or suppliers of surveying and data processing solutions such as Leica Geosystems / Hexagon?

From my point of view, the essential requirements are the topics “Data Sharing”, “Process Automation” and “Usability”.

Data Sharing: The exchange of data between different, heterogeneous system landscapes must be enabled or supported. For this, we need standardised data formats and seamless communication interfaces, in other words: interoperability. Only in this way can the data from a 3D laser scanner, for example, be transferred and processed without problems and loss-free in the most diverse CAD systems. Furthermore, the principle of “single source truth” is an important aspect so that the most recent data status can always be identified and communicated to all process participants.

Process Automation: We need systems that can automatically extract information from unstructured data such as point clouds, photos or videos. For example, this is important to carry out a TARGET-ACTUAL comparison for documentation or progress monitoring, ideally also automated or at least partially automated.

Usability: User-friendliness is generally very important for devices and software products and a decisive factor in how users accept these systems. Our employees are experts in the construction sector, and they should concentrate on their tasks. Therefore, they should require no special IT expertise for operation.

In your opinion, what is Leica Geosystems contribution as a sensor and measurement technology manufacturer to advancing digitalisation?

Leica Geosystems’ contribution lies in its bridging function between the real, analogue world and the digital world. The analogue world is about capturing the environment with sensors and measurement technology as precisely as possible and as easily and quickly as possible for the user, as is already possible today with the BLK2GO. The transfer of information from the analogue to the digital world should be loss-free and automated as far as possible, without significant intervention by the user, so that information is available in the cloud, for example.

In the digital world, a lot of work can be taken off the user’s hands if the recorded data is processed so that, for example, a simple target/actual comparison is possible in CAD or BIM. The reverse data flow from the digital to the real world is also exciting, e.g. the projection of boreholes using lasers or data glasses such as the Hololens would be conceivable.

Mr Kamenschek and Mr Beer, thank you for your thoughts on the future of the construction industry.

To learn more about our laser scanning solutions follow the link: https://leica-geosystems.com/products/laser-scanners

To learn more about the Boston Dynamics Spot combined with the RTC360 follow the link: Leica Geosystems Offers Mobile, Agile 3D Reality Capture Solution for Boston Dynamics Spot