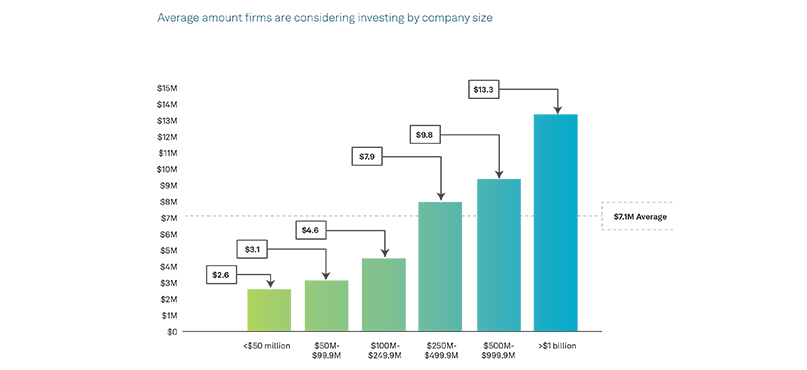

The construction industry is undergoing a significant transformation as it adopts new autonomous technologies to embrace more sustainable practices and innovative methods to improve efficiency, productivity and sustainability in the built environment. As part of its Autonomous Construction Tech Outlook, Hexagon recently surveyed over 1,000 senior leaders from general contracting firms about this transformation and found that 84% were already using autonomous technology in their operations, with 54% planning to spend between $5 and $15M on autonomous (or automated) technology in the next three years.

At the heart of this transformation is data-driven decision-making. Collating and analysing the data collected throughout the lifecycle of a project can help identify patterns, optimise workflows and improve construction methodologies. Reality capture technology enables autonomous construction processes by providing firms with accurate data, facilitating virtual modelling and simulation, supporting real-time monitoring and control, enhancing safety measures and fostering collaboration. By leveraging reality capture data, autonomous construction systems can improve the quality and timeliness of construction projects.

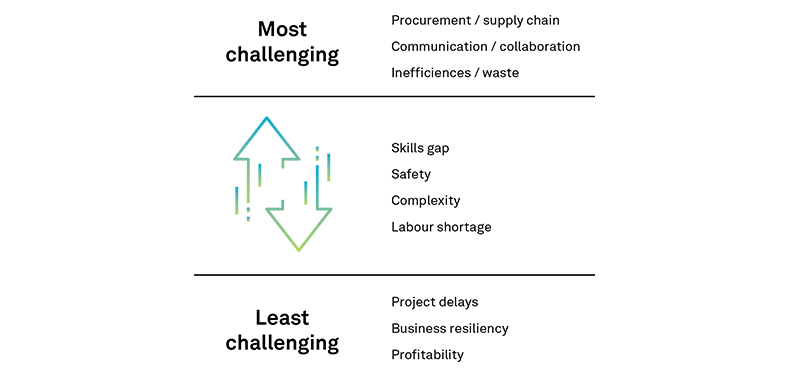

Respondents to Hexagon’s survey cited operational issues, including supply chain (39%), productivity/efficiency (36%) and labour shortages (35%), as their most pressing near-term challenges. Autonomous technology is central to helping firms address these short-term priorities. For example, reality capture systems — such as autonomous laser scanning modules and flying laser scanners — can be used for site surveying, mapping and monitoring. They can perform repetitive tasks with greater speed and precision. Turner Construction Company, for example, already benefits from successfully integrating autonomous scanning into its workflows, resulting in significant time savings of hundreds of hours. They identified that data captured from scanning is essential, but walking a site and scanning isn’t the best use of people’s time and abilities. Autonomous laser scanning freed up people’s time for higher-value tasks associated with keeping to schedule, quality and safety on a project.

There are four key areas of construction projects in which reality capture technology is helping to advance autonomy: documentation, quality assurance, safety and sustainable practices.

Precise and detailed documentation

Precise and detailed documentation

Capturing the as-built conditions through reality capture technology creates a digital representation, or digital twin, of the construction environment. This data can be used to analyse the site, identify potential obstacles and plan the construction process more efficiently. Over 20% of firms surveyed use automated data capture as part of their autonomous technology stack. This digital twin can also be used to simulate different construction scenarios and test the feasibility of various approaches. By running simulations, autonomous construction systems can optimise processes and identify potential issues in advance, ultimately helping to reduce waste.

Monitoring for quality assurance

Monitoring for quality assurance

Reality capture technology is also put to work for real-time monitoring of construction sites. Robots equipped with advanced sensors, such as the Leica BLK ARC autonomous laser scanning module, can monitor and inspect construction sites, capturing live data to compare it to the digital twin or reference model. This enables project managers to detect discrepancies, track progress and make adjustments as necessary, ensuring that work is done according to specifications and identifying any defects or deviations from the plan. This can lead to higher-quality construction and reduced rework.

Enhancing safety through autonomous tech

Enhancing safety through autonomous tech

Safety is a crucial aspect of the construction industry, and autonomous technology has the potential to enhance safety standards. Autonomous systems leverage reality capture data to identify potential hazards in the digital twin and plan and execute construction tasks with safety in mind. Also, by automating hazardous tasks or taking over heavy lifting, autonomous devices can minimise the risk of accidents and injuries to human workers. The Leica BLK2FLY, for example, can scan dangerous or inaccessible areas that would pose a significant risk to a person operating a static 3D laser scanner, such as a facade or rooftop. By simply selecting a location within the map on a tablet computer, the BLK2FLY will create its own flight path to scan it quickly and safely.

Embedding sustainable construction practices

Embedding sustainable construction practices

Over one-third of leaders surveyed for the Hexagon Construction Technology Outlook consider sustainability their top business priority within the next three to five years. And those technology leaders who use fully autonomous robotics reported improved sustainability and reduced waste. Almost 38% of construction firms using fully autonomous robotics said sustainability was the most common benefit. In the case of autonomous reality capture, robots can scan sites daily and create data to identify any areas of concern, highlight issues and reduce rework. Assigning robots to repetitive tasks improves efficiency, helping firms to complete projects faster, freeing up skilled labour for other tasks and reducing the need to have costly equipment onsite longer. Sustainable building practices are more likely to be adopted when these practices also improve cost, quality and efficiency. The solution is to capture site data early and often and to continuously use and improve upon that data with real-time information from the job site.

Insights that deliver a positive impact

Autonomous technology has the potential to deliver a truly positive impact on construction processes and systems, with the insights derived from autonomous reality capture, in particular, creating job sites that are safer, more efficient, and less wasteful than ever before. This advancement will enable the construction industry to build a world where people and industry can thrive sustainably.

Patrik Durvik

Patrik Durvik

Vice President Business Development

Hexagon Geosystems division

Overcoming the data leverage gap: Unlock the potential of your construction projects by closing the gap between data captured and date leveraged! Autonomous technology, such as sensor-software solutions, collects, analyses and distributes data more effectively — leading to better project outcomes.