Reconfiguration work on plant sites is always a tough challenge; demanding exceptional preparation to ensure the associated high costs and time-intensive labour are justified. Whether layouts are combined to form a new plant, or units are installed and utilities modernised, any plant reconfiguration project should start with the gathering of high-quality site data. This information should represent the plant environment in flawless detail so designers can plan with confidence.

The Leica RTC360 3D laser scanner is the ideal solution for producing as-built documentation for complex plant projects, empowering users to measure and capture the built environment in 3D in a fast, agile and precise way. It minimises surveying time for vast plant sites, and efficiently delivers in inhospitable conditions while preserving high accuracy and resolution.

Step 1: Capture accurate data with confidence

Plant reconfiguration projects are complex and time-consuming, where entire sections of the plant may need to be replaced, involving detailed engineering and the possibility of extensive above-ground piping. With the RTC360 solution, you can prepare in the right way by capturing the environment with a high level of precision.

Capturing accurate data is important especially when replacing, updating or adding any piece of plant equipment: measurements of the available space need to be flawless to ensure the new part fits. Precise documentation of the as-built condition of existing plant environments enables you to create error-free designs, ultimately saving you time and money on your plant reconfiguration project.

Improving the world of measurement and survey for nearly 200 years, Leica Geosystems has designed the RTC360 with efficiency and intuitive operation in mind. This innovative product has a measuring rate of up to 2 million points per second, capturing crisp, detailed scans with one-touch operation. A full-dome scan is completed under 2 minutes, creating coloured 3D point clouds.

With the RTC360, you can be completely confident that the data you capture is high quality and accurate:

- It collects images using 3 x 12MP cameras placed on the frame and 5 High-Dynamic Range (HDR) brackets in 12 shooting positions

- A resulting amount of 180 images are collected for each setup, and the total RAW images resolution is 432 MP

- These source images have a native resolution designed to match the highest-resolution scan setting on the RTC360, which is 3 mm @ 10 metres

- When considered as a panorama (in which the source images overlap each other), this is equivalent to 200 MP

Step 2: Improve efficiency, accuracy and safety

Whether you’re installing new units or upgrading existing equipment as part of your plant reconfiguration project, data tagging in the field will improve efficiency and eliminate the need for site revisits. This is a vital point that relates to the health and safety of your team: the rebuilding of complex plants is not only difficult but presents major hazards, so the less time spent in these inhospitable environments, the better.

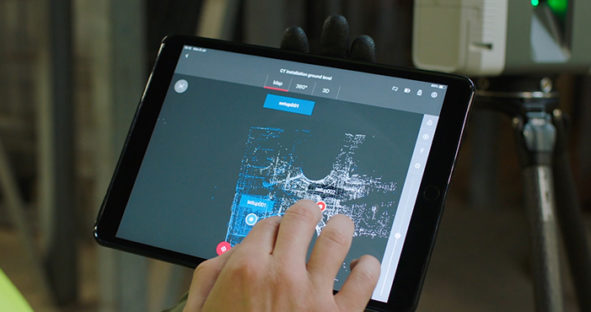

As part of the RTC360 3D reality capture solution, the Leica Cyclone FIELD 360 mobile device app links the high-quality data captured in the field with post-processing activity in the office. It offers added functionality that makes documentation of the built environment even more detailed and accurate. The importance of having the highest quality data possible cannot be underestimated: users can measure and visualise entire environments in millimetric detail and explore the created point clouds with total freedom.

With Cyclone FIELD 360, you can add tags anywhere on your captured scan data in the form of measurements, videos, images, voice files and simple text. This on-site tagging within the geometry of the 3D point cloud on your smartphone or tablet computer is fast and simple, improving the quality of your captured data and 3D models. The full data, complete with annotations, is transferred when it’s moved from field to office for improved interpretation.

The RTC360 minimises the amount of time spent on site collecting data through its fast operation and compact, portable design. Scan hard-to-reach areas, obtain up-to-date as-built documentation, then work with the high-quality data from the comfort of your office.

Find out more about how the Leica RTC360 3D reality capture solution can help you with plant reconfiguration projects:

RTC360 podcast with Juergen Mayer

Discovering the power of scanning Q&A