Plowman Craven, one of the largest surveying companies in the UK, played a vital role in the development of the Leica RTC360 3D laser scanner, contributing ideas that helped shape its features and functionality.

Having enjoyed a long and successful partnership that dates back more than half a century, Plowman Craven and Leica Geosystems met in 2014 in pivotal talks to share thoughts on what future hardware and software solutions might look like and what industries need to ensure accurate measurement of the built environment.

Four years later, the Leica RTC360 3D reality capture solution was launched, empowering users to document and capture their environments in 3D in a fast, agile and precise way.

We caught up with Dave Norris, Technical Director at Plowman Craven to explore the partnership and the development of this groundbreaking product in more detail.

Let’s take you right back to the start. How was the product concept conceived?

We were asked to share our ideas about future technology and what we would need and require. When Juergen Mayer, Hexagon Geosystems’ President Reality Capture shared his vision, it was clear that both our thought processes were aligned and we both saw an ambition to combine laser scanning with photogrammetry in a single device where you would get the best of both worlds.

It was about getting more out of the device than just measurement and understanding that the imagery was as important as the laser measurements – and, crucially, that the imagery could be used for more than just pretty pictures and assessing condition.

We proposed that the device could also be used for positioning and to extract measurement through photogrammetry. The question was whether combining the measurement world of photogrammetry and the measurement world of laser scanners would provide a single solution where 1+1=3. That is what Juergen and his team went away and developed.

What were the main stages of product development that you were involved in?

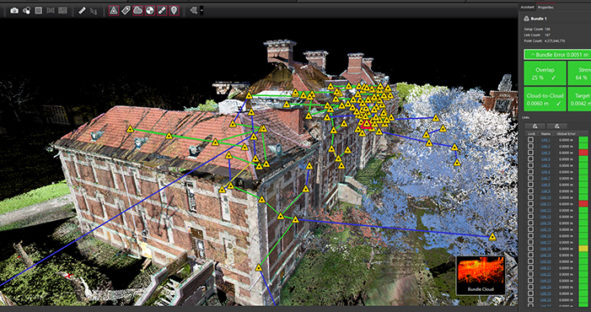

In terms of hardware, our involvement was really industry expertise, sharing some concept ideas at the beginning, back in 2014, and reviewing the beta version four years later. Our main involvement was with the associated Leica Cyclone software, including Leica Cyclone REGISTER 360. We’ve been part of Leica Geosystems’ Customer Council since 2012 – which gives us direct access to the development teams and

their roadmap – so we were able to contribute ideas and recommend features for Cyclone REGISTER 360 to complement the hardware.

What was involved in the collaboration with Leica Geosystems, from inception to completion?

Over a period of four years, we provided industry input to the reality capture and hardware teams. The contribution of our expertise and insight is probably best described by the key people at Leica Geosystems.

Juergen Mayer, Hexagon Geosystems’ President Reality Capture, said, “It’s thanks to the close and continuous ideas exchange with industry-leading service providers like Plowman Craven that we have been able to conceptualise and develop products like the RTC360.”

Faheem Khan, Hexagon Geosystems’ Vice President Business Development, added, “The RTC360 is part of a wider initiative that has re-examined every aspect of the reality capture value chain, to meet the needs and take onboard input from experts such as Plowman Craven, as well as others from different industries. The result of this is a redesigned tool-chain that delivers efficiencies in the capture, management, visualisation and consumption of reality capture data. We sincerely thank Plowman Craven for its strong involvement and support.”

Did you work on the development of any other Leica Geosystems products prior to the RTC360?

Over the last 20 years, we’ve provided input and feedback into a few different hardware and software solutions, aligning our industry experience with Leica Geosystems’ tremendous development capabilities. Ahead of the latest release of Cyclone and Cyclone REGISTER 360, we provided over 50 software requests, many of which have been incorporated by Faheem Khan and his development team.

Some of the features that did make it into Cyclone 9.4 are having a real benefit to our business, with the storage of less data, more automation and shortening the ‘field-to-finish’ project lifecycle. This is particularly important to us given the large scale that we operate at. With more than 3,000 scans hitting our network every week, and more than a petabyte of scan data already captured, we face some really unique challenges, specifically around data storage and flow. So we have to give them all the credit – we just provided ideas, feedback and industry experience.

How long has Plowman Craven been investing in Leica Geosystems’ equipment and laser scanning technology?

We provide a lot of different services for a diverse client base, and we use laser scanning in every part of our business. As a result, we’ve invested in every generation of terrestrial laser scanner over the last 20 years – from the Cyrax 2500, HDS3000, HDS4500 and HDS6000 through to today’s Leica ScanStation P40, RTC360 and BLK360, every generation has brought a step change in performance for our business.

Any final thoughts?

Where to even start? The Leica RTC360 is tremendous. We could talk about how fantastic the Visual Inertial System (VIS technology) works, how fast it makes workflows, how it reduces the amount of post-processing, the speed of scanning, the quality of images, the end-to-end workflow.

We think it’s an outstanding piece of development. The advanced technology presented through such a simple user interface takes away the complex challenges we would normally face with scanning and registration. To automate and simplify that process using a combination of all the different sensors is, quite frankly, unbelievable.

Think of the technology that is inside an RTC360 device… Visual Inertial Systems, IMU, GNSS, HDR imaging cameras, thermal sensors, and a laser that measures at 2 million points per second. In the past, you would have needed something the size of a filing cabinet! Leica Geosystems has got it all working in a single unit that you can just pick up and put in a rucksack. It’s incredible what Juergen and his team at Leica Geosystems have done and they all deserve a huge amount of credit for it.

For more details on the Leica RTC360 3D reality capture solution, click here, or if you would like to discuss how it could benefit your organisation, simply contact us today.