Clinton Mätkonsult, one of Sweden’s leading survey consultancy firms specialising in 3D laser scanning, has played a key role in several large-scale development projects in Stockholm. Their scans create a digital foundation upon which future work can be designed and displayed and current work can be checked to ensure accuracy and stability.

Recently, they were part of two major projects to expand, renew and develop urban infrastructure and areas in Stockholm, including:

- Extending Stockholm’s Blue Line underground metro track to reach more residents and offer smarter routes.

- Transforming Stockholm’s former industrial meatpacking district, Slakthusområdet, into a sustainable and vibrant urban community.

In this blog, the Clinton Mätkonsult team members share four key benefits of using Leica Geosystems’ laser scanning solutions on these projects to enable efficient and accurate data collection even in demanding or difficult situations.

1. Get the data needed to plan and progress quickly

1. Get the data needed to plan and progress quickly

With Stockholm’s continuing growth and increasing demands on public transportation, the city initiated a major ten-year project in 2020 to expand the city’s Blue metro line. When operational, the entire route will be underground and shorten travel times for Stockholm residents.

However, three working tunnels were required to transport personnel, machines and materials necessary for construction before creating the rail tunnels. These working tunnels, which have steep slopes and sharp curves, needed to extend about 1,300 metres.

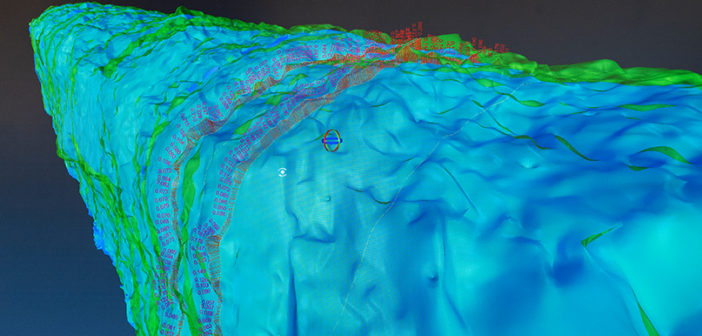

The working tunnels were created approximately five metres at a time using drilling, blasting, scrapping and unloading. Once the rock debris was cleared, scans were made of the outer contour of the tunnel. Next, rock reinforcements were added, after which the tunnel was scanned again to capture the inner contour and validate the reinforcement.

Clinton Mätkonsult’s use of 3D laser scanning solutions, including the Leica RTC360 scanner and Leica Cyclone 3DR point cloud management software, provided accurate, fast and detailed information about conditions and progress. Pheng Zang, Head of Measurement at Clinton Mätkonsult describes the importance of the scans for enabling the safe advancement of the working tunnels:

“Our mission is that the working tunnels end up in the right position and get the right dimensions. Our measurements and tunnel contour models also form the basis for documenting and showing the contours of the tunnels before and after the rock reinforcement. This material forms the basis for decisions during the work and is the basis of the relationship documents.

The fact that we can report our work quickly means that the construction management has a good foundation to make well-thought-out decisions at an early stage: making further rock reinforcements or removing encroachments.

The quality increases and measures can be taken immediately, which leads to less risk of price increases or delays. For us, this leads to a satisfied customer and that we can work better and spend time on the right things.”

2. Scan and process despite environmental or situational challenges

2. Scan and process despite environmental or situational challenges

The right 3D laser scanning equipment can make a big difference in speed and outcomes, especially in unusual or difficult environments like the working tunnels tight, steep shadowy conditions.

While the Clinton Mätkonsult team often uses the Leica ScanStation P40 on jobs, for the Blue Line project Zhang chose the RTC360 because the equipment operates quickly and is easy to move.

“These are important advantages because working tunnels are often a few hundred metres and have steep slopes, sometimes up to twelve percent,” says Zhang. “It is also not always possible during the construction period to transport yourself by car.

Making frequent measurements and walking with heavier laser scanning equipment can be time-consuming and physically demanding. The weight and flexibility of the RTC360 and the carbon fibre tripod we use make it much easier for us.

We work in all the tunnels in parallel and sometimes the need arises to scan in several places more or less at the same time. Therefore, fast and easy-to-handle equipment is very important for us to carry out the work and move quickly.

If the rock’s conditions are worse, it is only possible to operate a tunnel a couple of metres at a time to make the work as safe as possible. We usually scan ten to fifteen metres at a time and do it from two different positions to ensure that we get everything and that nothing ends up in the shadows.”

3. Create fewer disturbances for third parties

3. Create fewer disturbances for third parties

When real estate developers Atrium Ljungberg acquired Slakthusområdet in Stockholm for an expansive sustainable urban development project, they contracted Clinton Mätkonsult to digitally capture the area through 3D laser scans and create BIM models to prepare for renovations and new construction.

The Slakthusområdet development will transform the former industrial meatpacking district into a vibrant community featuring food, culture and experiences. Thousands of new homes and workplaces are planned with a focus on preserving historical buildings where possible and ensuring new architecture matches the charm of the existing area.

The scanning project, which began in 2019 and was completed over a year later, required the firm to scan 50,000 square metres in 11 properties, comprising 600 hours of scanning work. One large challenge was to complete this high volume of scans while limiting the impact on area tenants operating various businesses, including bakeries, slaughterhouses, event companies, art studios and breweries.

The flexibility, speed and portability of the Leica Geosystems laser scanning solutions allowed the Clinton Mätkonsult team to complete their work while tenants continued full operations. Victor Nyström, Regional Manager at Clinton Mätkonsult, describes how it was possible to accommodate the tenants while maintaining effective workflows:

“We worked with great flexibility and often jumped between the different premises. When the pandemic struck, it did not get any easier, but everything could be solved with consideration and communication.

Because we moved around often, we had to handle up to 100 subprojects in the scan. Therefore, it was absolutely crucial that the scanning equipment and the point cloud processing office software, Leica Cyclone REGISTER 360, were easy to use. It went very well to include several small projects in the large project, which simplified the work of compiling all the data that was registered.”

4. Enhance productivity and sustainability through digital collaboration

4. Enhance productivity and sustainability through digital collaboration

The Slakthusområdet project also demonstrates the ways that 3D laser scanning enables digital collaboration, as Nyström describes below:

“In this project, digitisation has been a success factor. Everyone was able to log in and follow the scan results in the Leica TruView digital reality viewer and gained a great deal of awareness right from the start. Then when the pandemic came, it became even more important that everyone could see all the details from each property via their computers, as it was no longer possible to get out to the area for physical checks. Digitisation was a great success on many levels.

By collaborating digitally, we have reduced the risk of delays and reduced travel, with associated carbon dioxide emissions. We have been able to work with a high quality where everyone had a common platform to start from.

The positive feeling applies to all disciplines in the project. My experience is that everyone involved as architects and designers felt that the work went smoothly. It has been easier for everyone to be part of the process, they have continuously seen data enter the TruView digital reality portal, it has been easy to ask questions and review the model in good time. No one had to go on-site to do their own checks.

Atrium Ljungberg is satisfied with our work and we have already started new projects where we work in the same way. There is time and money to be saved by 3D laser scanning and making digital models that anyone can use. With the right data from the beginning, the result will be better all the way to the end and it does not have to be about such large projects as the Slakthusområdet for it to be profitable.”

While both projects are years from completion, Clinton Mätkonsult has helped lay the foundation for future success through their laser scanning contributions.

You can learn more about how 3D laser scanning benefits urban planning projects here.

Megan Hansen

Communications Specialist

Leica Geosystems AG

Visit our Pure Surveying website for content for every skill level across all sectors, from how to grow your business with laser scanning to how to improve your skills.