You might think that a tripod is a simple piece of kit and that one tripod is going to be as good as any other. However, that underestimates the effect that a stable base (or lack of one) has on surveying equipment. If your survey solution includes a dodgy tripod or tribrach, regardless of the quality or the cost of your total station or 3D laser scanner, the measurements you take will not be accurate. Here we look at the quality standards that tripods and tribrachs need to meet and the lengths that we go to at Leica Geosystems to exceed them. While we ensure that our tripod and tribrach accessories perform to a warranted quality standard, some third-party suppliers do not. We look at how poor quality accessories can affect your work, and finally how you can spot a fake.

The job of a tripod and tribrach

A tripod is a highly accurate piece of mechanical engineering. It needs to withstand a lot, from being thrown in the back of a van, to years of exposure to the elements, from hot and humid weather to freezing temperatures. It needs to support heavy and rotating instruments, while absorbing vibrations from heavy machinery or passing traffic. A tribrach – the attachment plate used to attach a surveying instrument to a tripod – has to cope with the same. While a well-built tripod can last for years or even decades, a poorly built or designed tripod or tribrach will soon start to distort, leading to false readings.

Tripod standards: ISO 12858-2

Tripods should be built to certain standards specified by the International Standard (ISO 12858-2). This covers height stability – how much weight a tripod can support – and torsional rigidity – how well it copes with being rotated before it distorts in shape. According to the ISO standard, tripods can be classified as either heavy- or light-weight. A heavy tripod can support instruments up to 15kg, while lighter tripods are suitable only for instruments weighing less than 5kg. There are a couple of tests set out by the standard, which we look at below. Leica Geosystems performs an extra test on its tripods and tribrachs to give customers a greater level of confidence.

Testing that tripods and tribrachs meet quality standards

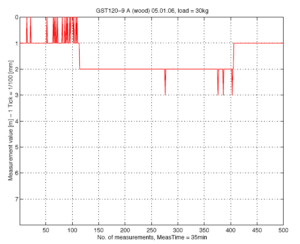

Image 1 – Leica GST120-9 tripod height stability test results.

A “static load test” is used to measure how well a tripod handles weight. To pass the ISO test the position of the tripod head may not move up or down by more than 0.05 mm even when carrying double the maximum instrument weight. Clearly, a user does not want the tripod to vertically distort over time while measuring points – the instrument height would be changing and the points would be wrongly measured.

Typical results for the Leica GST120-9 wooden tripod are shown in Image 1, where the tripod was loaded with a 30kg weight and monitored for 30 minutes. Note that not only is the vertical change well within tolerance (0.05mm), but once the load is lifted, the tripod returns to (almost) a zero deflection, that is, its exact starting point.

The second ISO test – “torsional rigidity” – looks at how well a tripod copes with being rotated. When the instrument its supporting rotates, the forces affect the tripod head plate. The torsional rigidity is a characteristic of the tripod to absorb this horizontal rotation by returning to its original position when the instrument is stationary. This rotational force is particularly high with robotic instruments as they accelerate and decelerate.

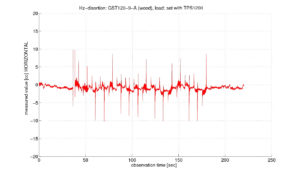

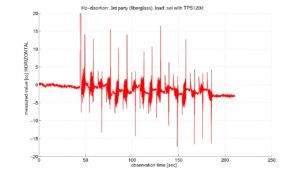

At Leica Geosystems, we perform an extra test to check how rotation affects the tripod over a longer period, referred to as horizontal drift. We use our Sets of Angles app to repeatedly measure two points, providing rotational forces in both directions as the instrument turns to each point. A subset of typical results for the Leica GST120-9 wooden tripod are shown below. Each peak in the graph is the point in time where the instrument accelerates or decelerates causing a temporary distortion in the head of the tripod. Notice that the tripod almost instantly returns to zero distortion once the instrument has finished accelerating and decelerating. With a lower quality tripod, we would expect to see a drift which would affect the accuracy of measurements taken. If you had invested in a highly accurate instrument, then much of the investment would be wasted because the tripod would hamper its ability to perform precisely.

Image 2 – Leica GST120-9 tripod Torsional Rigidity test results

Image 3 – Third-party tripod Torsional Rigidity test results

Leica Geosystems attention to detail: from tree to tripod

Our heritage in developing surveying instruments means we have spent nearly a century improving our design and manufacturing processes. Our tripods are manufactured usually from wood or aluminium. Wood offers the best stability values, measured on vertical movement and horizontal drift over time. It’s also the best material for handling vibrations. For the strongest tripods (our Professional 5000 range recommended for motorised TPS instruments), we have found that the best wood to use is beech, and not just any beech, but wood from trees grown on north-facing slopes on dry, sandy ground. Its slow growth makes it more dense and best suited for carrying weight. We have also found that the wood should be stored for a least a year to slowly dry and reduce the risk or cracks or areas of weakness. The surfaces of our wooden tripods are sealed several times to prevent moisture absorption and make them last as long as possible.

Inaccurate measurements: is a ‘Leica-like’ tripod or tribrach to blame?

Failure to understand the role of the tripod and tribrach in getting accurate measurements means you might get false readings but have no idea why. Leica Geosystems customer service and product management teams investigate any reports from customers that a Leica survey solution is not giving accurate results. We often find that the problem is being caused by third-party accessories, many claiming to be ‘Leica-like’.

For example, we worked with one university to identify why a postgraduate student, who was carrying out measurements with a Leica robotic total station, was experiencing problems. After much investigation, including a full service and inspection of the instrument, the local support unit accompanied the student to the test site. Within five minutes the problem was identified: the university had purchased a third-party tribrach. Once it was replaced with a genuine Leica tribrach the results were immediately within tolerance and as expected.

Spotting a Fake

Image 4 – Example of QR code of a genuine Leica Geosystems accessory

A cheaper tripod or tribrach might be tempting, but as we’ve seen above it can end up being much more expensive in the long run. Not only do you need to buy the appropriate tripod and tribrach eventually anyway, but you have to re-do your work, spending double the time on site. And of course, no one ever wants to be the cause of delay to a project. So how do you avoid buying the wrong accessory?

Because the quality of Leica tripods and tribrachs is so well known, they are often copied – without having a warranted quality standard. It can be difficult to tell by looking whether a product is real or fake, especially if you are buying online from photos only. To combat this, Leica Geosystems’ original accessories now come with unique security codes that guarantee that what you bought is truly a part of the Leica Geosystems complete solution. You can verify a product by entering its code online at the Leica Geosystems MyWorld portal or by scanning the QR code using any QR code reader. For tribrachs, the code will be found inside the box. A genuine Leica Geosystems accessory comes with an exchange and replacement parts guarantee to give you peace of mind. For some products, we even guarantee to replace parts even if the product should be discontinued.

Find out more information here: Leica Geosystems tripods and tribrachs.

Gerhard Soenser

Product Manager Accessories

Leica Geosystems AG