Over the last years, the construction industry, among other industries, takes advantage of the benefits of digitalised data. As the concept improves, we are using digitalised data in more and more applications, hence, it is easier to collect and manage data that is digitalised.

Digital data can be processed, transferred and stored easily, however, its true value is if the collected data can be used efficiently. Time is money, and in the construction industry, time is even more costly as factors such as hiring an excavator, assigning a crew for a job, and traffic management have a big impact in the cost of a construction site. Therefore, it is critical to work efficiently.

There are two main purposes for utility detection:

- Utility mapping

- Damage avoidance

For Utility Mapping, transferring the buried utilities into digital maps is essential for asset management and planning, this is mostly done for larger areas and an onsite application follows later. On the other hand, utility detection for damage avoidance is performed shortly before the onsite application starts. Very often utility detection starts when the excavator is already on site waiting for the utilities to be marked on the surface so that the excavator can start digging. As you can imagine, accessing the results instantly is very important to start digging and this affects the overall project costs and job site management.

Electromagnetic locators and radar technology

Detection of buried utilities requires to use different technologies and products; electromagnetic locators (Leica DD Series) are used for detecting cables and metallic pipes and radar technology (Leica DS2000) is used for detecting both metallic and non-metallic utilities.

Leica Utility Detection solutions for avoidance and mapping, allows you to make onsite interpretation and convert results to CAD files. With the DS2000 and the Leica GG04 you can have the results with absolute coordinates and create a CAD file with these coordinates.

Software solutions

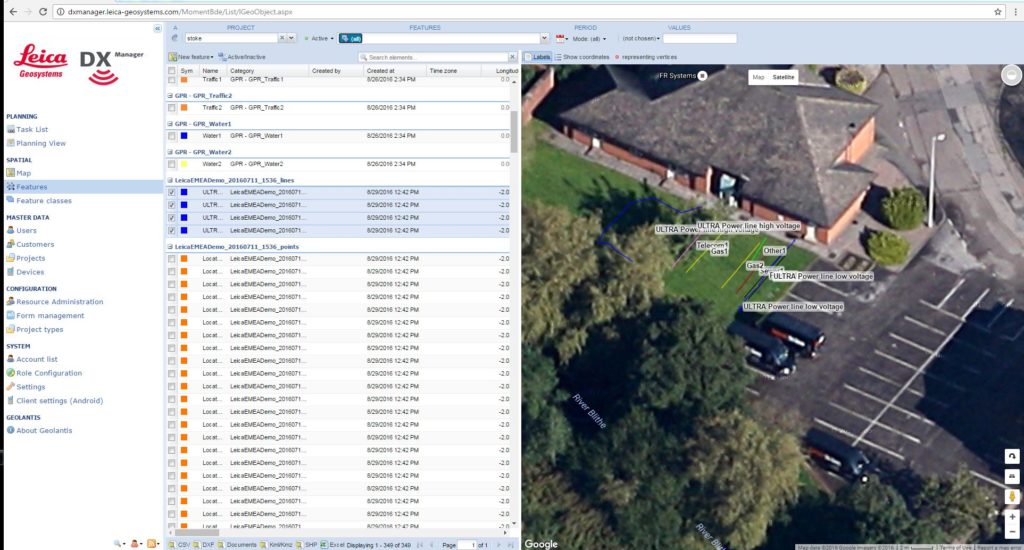

The acquisition software uNext, used with the DS2000, allows adding the results of the Cable Locators as a part of the field interpretation. The interpretation results can then be converted to CAD files. Also, Leica DX Office Vision post processing software can be used on the field to process the data from theDS2000. Thanks to its ease of use, the post processing software can be done on the field in a short period of time. To make digitalisation of data even more convenient, it can be merged on Leica DX Manager Mapping.

Making data accessible for the operator

After locating and mapping utilities in the field it is time to make the collected data easily accessible for the excavator operator. Of course, the results can be marked on the surface but after breaking ground these marks will also disappear. Bringing digitalised data in front of the operator will increase efficiency and reduce the risk of damaging utilities and having utility strikes.

The CAD file, which has been created on the field, can easily be uploaded to Leica ConX, the machine control platform where the uploaded data will come to the control panel of the excavator instantly. Using ConX, the operator can see how close detected pipes or cables are to the excavation zone. If the excavator gets too close to the objects, an alert will warn the operator.

All these steps can be performed on site shortly before excavation starts. Site managers can plan their workforce more efficiently by avoiding waiting time to start excavation.

Click here to learn more about utility detection for avoidance and mapping.