3D laser scanning technology can be used in any project – from industrial buildings to tunnels, roads and rail – to make work faster, safer and keep it on budget. Here, heavy construction workflow expert Frank Collazo explains how Leica Geosystems customers are using 3D laser scanning on-site to compare work to design plans, take measurements, generate reports and share progress with stakeholders.

1. What are the most popular applications for 3D laser scanning in heavy construction?

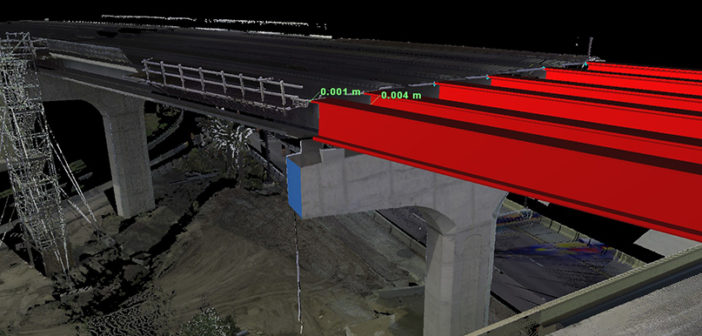

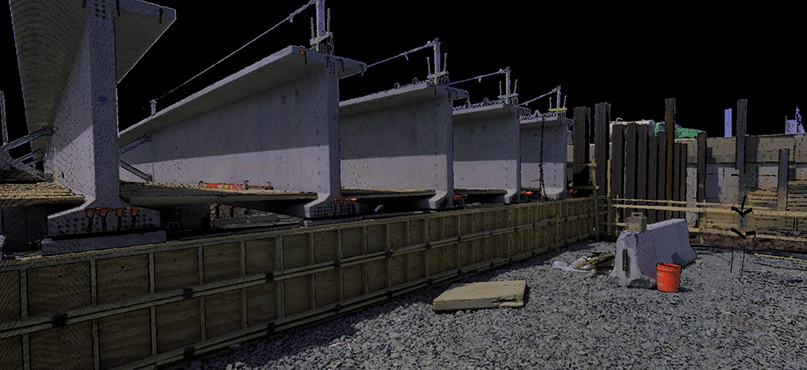

The most popular applications are in the larger infrastructure projects – roads, bridges and tunnels – where the potential to save time and simplify workflow is vast. These projects require the survey staff to frequently check work against a design because it’s essential that important infrastructure is built correctly. If it isn’t, the results could be disastrous. It goes without saying that an error in a tunnel, bridge or road construction is unacceptable, and 3D laser scanning is an extra tool to ensure it doesn’t.

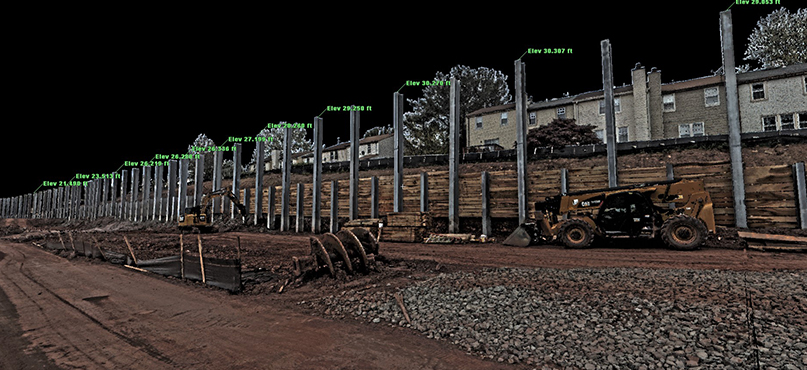

To give a specific example, one of our clients is working on a roadway project in Northern Virginia. They are using reality capture technology on a 22-mile stretch of the I-66 corridor. They scan as much as possible every day for earthworks and to check construction against design.

Other uses of scanning on this project are to monitor retaining walls for minute movement and to check the verticality of H-beams. There might be hundreds of beams per mile and the position of each one needs to be checked to make sure it will have structural integrity. With a 3D laser scanner, they can do one scan in two to three minutes and capture a large section of the site. This is faster than using traditional surveying equipment, which needs to be constantly repositioned.

2. What are the benefits of using 3D laser scanning on heavy construction sites?

3D laser scanning is excellent for projects where you need a high level of accuracy. For example, with road projects, it’s essential to have a smooth final surface. If you design a road and it isn’t built to the smoothness specified in the design, you will have more wear and tear than planned and create more maintenance for the highway agency and vehicle owners.

Laser scanning is the best way to capture the road surface precisely as it has been built. Because of the speed and ease of using a laser scanner, you can also re-scan more often than carry out traditional surveys. This means that you’re capturing more up-to-date and, therefore, accurate information.

Portable 3D laser scanners can map areas that are hard to reach. For example, UAVs are good at capturing some site areas, but they can’t always fly into tunnels or under low bridges. They also can’t see through a heavy tree canopy. With the handheld Leica BLK2GO imaging laser scanner, you can walk through difficult sections and capture the data you need as you walk.

Safety is another significant benefit. For example, if you want to measure the volume of different materials, you can do that from ground level with 3D laser scanners. Using a GNSS pole, you would need to climb onto the stockpile to measure the top, increasing the risk to your safety. It’s the same with measuring embankments or features that are high up. With a laser scanner, everything can be done more safely from ground level.

Not only is it safer and faster, but it’s now also easier to learn than conventional surveying methods.

3. If you haven’t used 3D laser scanning in heavy construction before, does it require much training?

Not at all. The hardware is really easy to learn and use, even for companies who don’t use that much technology. 3D laser scanning has come such a long way.

When I started working for Leica Geosystems almost 18 years ago, I was a trainer and part of the team that wrote training manuals and delivered training. Back then, depending on the scanner, training was a five-day course with a follow up a month later. Now, some of our laser scanners have one button operations and pre-sets – for example, the Leica BLK360 and Leica RTC360 – so it could be as simple as 15 minutes or a video and phone call.

If you want to use a laser scanner with more complex functions, say you want to learn how to use a Leica ScanStation P-Series scanner to traverse and resection, then that takes a bit longer. However, it’s still a process that becomes familiar very quickly to surveyors: set-up over known control, level, and backsight.

4. What software applications do you need to get the most from a 3D laser scanner?

I like to think of this in two parts. Firstly, you have the software you need to use with every 3D laser scanner to import and register the data you have collected in the field: this is the initial processing. Secondly, you will need different software depending on what you are collecting the data for. What is your final deliverable?

For the initial processing, you need Leica Cyclone REGISTER 360. It’s the same office software for most of our 3D laser scanners, and it handles importing and registration. Registration is the process of bringing all your scans together into one coordinate system. This is very simple now that some of our laser scanners include sensors like an IMU, VIS (Visual Inertial System) and GPS, which keeps track of the scanner location in the field.

These sensors mean that you don’t have to tie all the scans together; the in-field Leica Cyclone FIELD 360 software does it automatically. That’s a huge time saver. Before these sensors were introduced, it would often be challenging to tie scans together – especially if this was done by a different person back in the office – because it wasn’t always obvious which order the scans had been taken in. Now it doesn’t matter.

The secondary software you need depends on what you are going to use the data for. To go back to our road project example, if you want to use the scans to check the existing conditions or the new road against the design, we’ve got a couple of great tools for that.

I like Leica Cyclone 3DR, because it’s multifunctional. Not only does it do all the checking against the design, but it also does an automatic data clean. Imagine in your scans you have captured loads of machinery and people walking around. Maybe some brush and trees too. With some software, you would need to manually remove these features. In Cyclone 3DR it’s as simple as a couple of clicks.

It is also incredibly useful to generate automatic reports that you can share with your client. These can be customised so that you’re adding the most value to the project. We know that clients find these reports impressive, and it has helped our customers to get more business.

5. Can you give us an example of a simple workflow using Leica Geosystems free TruView digital reality viewer?

I love how our clients use Leica TruView, digital reality viewer, to share information with different people working on a project.

Large construction companies have many other divisions which need to check the site data or use the site data in different ways. With TruView, everyone has access to the same up-to-date information online. They can see what the conditions were on site on what date. They can go back and see how things have changed between scans and how much progress has been made. Everyone can see the same level of detail.

It’s a considerable time saver for all divisions. For example, now the construction office isn’t having to call the surveyor to ask if they can tell them the distance between this post and that post, or the size of that stockpile because it’s right there in the scan. They can check for themselves online.

It brings confidence to the whole team too. Everyone can be deeply confident with the scan data collected because they can visually see they are in the right place.

It reduces misunderstandings because anyone with questions can digitally mark up a view. For example, if you want to check the verticality of a specific beam on a site with thousands of beams, you can mark it in TruView and everyone will know which one you are referring to. Misunderstandings are one of the top reasons why surveyors have to go back out in the field – “Guys, you didn’t survey what I asked you for, you missed by 50 feet, go back out there and get the rest” – with TruView you spend your time much more efficiently.

Frank Collazo

Reality Capture Specialist

Heavy Construction US/CAN

Follow Frank on LinkedIn to learn more.

For more information about Hexagon’s Heavy Construction solutions, visit our website https://heavyconstruction.hexagon.com

For more information about Leica Geosystems 3D laser scanning solutions, visit our website leica-geosystems.com