A digital twin is a digital representation of a physical object or system. Their business applications are found in several sectors such as manufacturing, real estate, construction, but still, their concept is unknown to many. Fabio Ponzio, vice president for Hexagon Geosystems Building Solutions and Andrea Paglialunga, business development manager at Geomap, share their digital-twin technology insights and explain how it can change future facility management.

- The term “digital twin” is often used by tech-savvy industry professionals, but what does it really mean?

Fabio: It depends on what context they talk about digital twins as there are different types of digital twins. It could be a digital twin of a single product, an entire building, factory, city and others. We like to refer to it as a digital representation of a physical object or, in other words, the fusion of the physical and digital worlds. For example, a digital twin of a building or factory helps you understand the present and gain intelligence from that data or create simulations based on different scenarios and predict future outcomes based on variable data. When it comes to buildings, these virtual representations transform how buildings are designed, constructed and maintained. For example, using a digital twin for operations and maintenance of a building provides owners and facility managers rich information and remote access to different spaces and building assets, which lead to productivity improvement and cost-saving in day-to-day operation. I’m sure Andrea could elaborate on how such digital twins can be created and used in day-to-day operations.

Andrea: I agree with Fabio. For us, a digital twin is a digital replica of a physical reality, in reference to the AEC field, of a building. To create a “digital twin,” there must be three main requirements: the physical products in real space, the virtual products in virtual space and, finally, the connections of data and information that link the products in these two worlds. Thanks to advanced reality capture techniques, such as laser scanning and point clouds, we can create 3D virtual models of buildings and infrastructures – the digital twins – which are a perfect copy of the original in every single component and process. Through the integration with CAFM/IWMS software, the digital twin offers the great advantage of being able to manage all building operations-related processes and FM elements, resulting in a decrease in maintenance costs, better building and asset performance. This cutting-edge technology is radically transforming the management model of a building.

- Can you give examples of digital twins used by your customers?

Fabio: I want to give you an example of a customer using our reality capture technology to create digital twins. Natisoft, located in Italy, is a firm that helps facility and property managers by providing digital as-built documentation of facilities, architectural plans of properties, and key directories of specific equipment, objects, or machines to clients. Its deliverables range from 2D floor plans to complex 3D models. Natisoft recently adopted the BLK2GO and discovered the great benefits of using this solution. They can create digital twins with this solution in a much more effective and time-saving manner.

Another example is the Plaza Santa Catalina shopping center located in Lima, Peru. They are using a digital twin created with our reality capture technologies integrated into a CAFM solution. The proper maintenance of an 11,000 square metres large building can be challenging. The digital twin helps the property manager to reduce the complexity of daily property management tasks. Combining a 3D digital twin and web-based facilities management software for portfolio management, location-based asset tracking, and preventive and corrective maintenance management increases transparency, productivity and reduces costs. Andrea can walk you through some other examples where reality capture technology has been successfully used and combined with the Geomap IWMS platform.

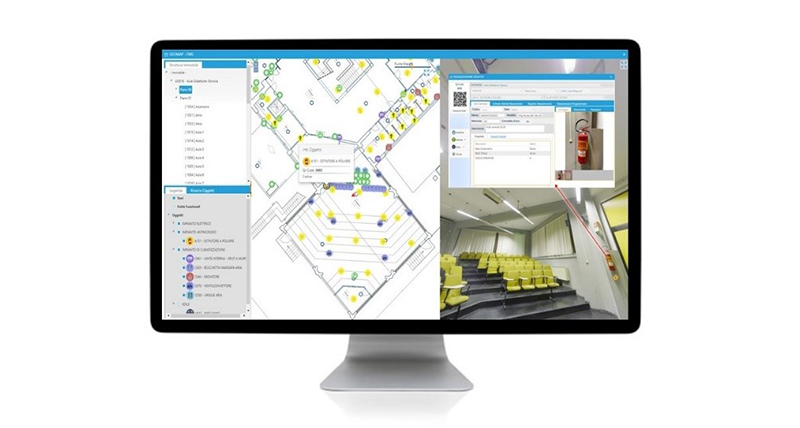

Andrea: Our customers have created a digital twin of their real estate portfolio to integrate it with Geomap IWMS and achieve 3D management via CAD support. A great example is the University of Sassari (Italy) with a surface of over 100.000 square meters. First, our team digitized the whole area using the Leica RTC360. Then, to have a perfect knowledge of all the building systems (fire alarm system, HVAC, etc.) and related assets, it was performed a geolocated asset collection and Qr-Code labelling through the Geomap Survey App. In this way, all the 3D data, technical data (model, brand, description, etc.) of the assets were collected, digitized, and now manageable in the Geomap platform. The result is a tremendous accurate digital twin of the spaces and all related assets. Managing such a wide portfolio, maintenances, and related operations with Geomap FMS will be much easier, cost-effective, and less time-consuming.

- Why should a company invest in digital twins?

Fabio: The key is to have the right systems in place to leverage the full potential of a digital twin. For example, using a CAFM or IWMS solution and combine that with an accurate digital representation of your building and asset portfolio improves productivity in daily operations. Facility and property managers don’t need to maintain traditional paper records of information; the digital twin serves as a dynamic real-time database. This way, they increase maintenance efficiency, enable remote management and share data with other stakeholders much easier. It’s a real game-changer giving facility managers more insights and geospatial information of their different building assets.

Andrea: Customers with a large real estate portfolio that have implemented the digital twin integrated with the Geomap platform reported a significant return on investment due to several factors. The most common benefits they have experienced are: remote inspections and a more safe environment; smart maintenances (increase of maintenance performance and asset life cycle) and reduced maintenance mistakes; data can be easily shared from several stakeholders. Complete knowledge of the real estate portfolio and related assets results in the launch of much more accurate maintenance tenders and bids.

- How will future facility management differ from today?

Fabio: I think digital twins of buildings and real estate portfolios will become more and more a standard tool for facility management. Driven by technologies like IoT, reality capture and others, the trend of having more connected systems and sensors will continue and provide more transparency and enable more predictive and automated facility management. These and other trends result in better building performance, quality, and an overall experience.

Andrea: Nowadays, relying on accurate and up-to-date data of a real estate portfolio under management is a priority for facility managers and related stakeholders. 3D management, with CAD support and up-to-date data of the assets integrated with a CAFM/IWMS, makes today clear to sector operators their significant economic advantages. Digital twin, machine learning and AI managed from a CAFM/IWMS will bring the maintenance and real estate management to a whole new level. Digital transformation in facility and asset management has already started and it will be crucial not to miss it.

Please connect with Fabio Ponzio and Andrea Paglialunga if you have any questions.