It’s no secret that underground mining is a major operation in Australia. Research from the Australian Bureau of Statistics (ABS) shows that total spending on mineral exploration in September 2021 has risen to the highest on record at over AU$925M. Surveyors are travelling to Australia from all over the world to work in mines more deep and complex than any they’ve dealt with before.

One of the latest technologies to help underground operators, surveyors and engineers is the new Leica Geosystems ScanCrete Solution. In this blog, we explore what ScanCrete is and how it has benefited underground mining activities in Australia.

Deeper dives in Australia’s mines

Deeper dives in Australia’s mines

Australian underground mining is getting deeper than ever. As the mines become deeper and more complex, there are stricter protocols around geotechnical ground conditions, ventilation and design. Luckily, geotechnical constraints at depth can usually be overcome by using multiple systems of ground support concurrently to provide adequate protection for miners and equipment.

Shotcrete is an example of this. It’s a sprayable concrete mixture applied with a mobile spraying unit at high velocity to areas of a mine that require extra support. Many mines in the Goldfields region of Australia use shotcrete with every cut. It can be described as “an added part of the cycle of work between bogging of blasted dirt, and the jumbo installing bolts and mesh to the mining front.” While this addition to the mining cycle can cause extended times and delays in metres advanced, projects can streamline and deliver repeatable quality of shotcrete by utilising survey scanning data, thus increasing safety assurance.

Introducing Leica Geosystems ScanCrete

Introducing Leica Geosystems ScanCrete

Leica Geosystems has developed a portable, fast and easy to use system that delivers shotcrete analysis for users to help the growing number of projects underground. ScanCrete is an end-to-end solution that enables instant as-built analysis and verification in underground hazardous environments using 3D laser scanning. It helps users perform real-time analysis for shotcrete applications efficiently, and quickly conduct as-built analysis of structures using intelligent sensors and software in the field or office.

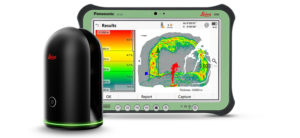

There are two Leica Geosystems laser scanner combinations available for ScanCrete – the Leica BLK360 and the Leica RTC360. Both options combine the Leica Captivate Inspect Layer App and Leica Cyclone 3DR desktop office software for final analysis of the collected data.

How ScanCrete works

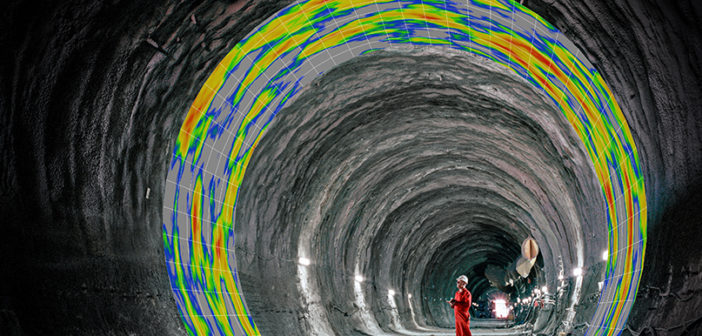

Users position either their BLK360 or RTC360 in the workface of the tunnel surface and undertake the initial scan. Shotcrete is then sprayed inside the tunnel and after completion, a second scan is then captured in approximately the same tunnel location. Once scans are completed, data is transmitted wirelessly to a tablet computer, running the Leica Captivate Inspect Layer App. The results from these scans are then analysed within the app to visually display if too much or too little concrete has been placed compared to the desired layer thickness using a heat map.

As required, users then apply additional shotcrete layers and complete further scans for comparison. The data can be geospatially referenced by utilising local survey control or storing as arbitrary positioned data. For construction records and shotcrete placement analysis, users can download this data wirelessly or via USB from the field tablet and further analyse the data in Cyclone 3DR in the office. Multiple scans can automatically be aligned via advanced data processing, which detects common features in the data and aligns these point clouds of overlapping scans to create singular data models for assessment.

Simple shotcrete application saving time, cost and waste

Simple shotcrete application saving time, cost and waste

ScanCrete simplifies the as-built inspection of the sprayed shotcrete layer-by-layer. It enables in-field analysis to enhance productivity, reduce waste from over-spray and increase quality assurance with real-time information on the worksite. Enhanced shotcrete application means that each load delivered to the spray hopper can be utilised to its full potential.

A previous article from UG Mining Tech states: “The main benefit of this is it allows the operator to check for any discrepancies between desired design thickness and actual applied thickness, while still being set up at the spraying front. It enables improved QA/QC of shotcrete application as the crew can ensure they have met the minimum design thickness requirements and not enter potentially hazardous, recently sprayed and unsupported work areas. It will even allow the nozzleman to gain valuable feedback on their spraying practices and reduce overspray through the system’s insights.”

Christian Jacobsen

Christian Jacobsen

Mine Monitoring and Survey Specialist

Radar & Monitoring Division

Hexagon Geosystems

At Leica Geosystems, we are committed to delivering solutions that contribute to safer and more efficient mining. Visit the website to learn more and read the full UG Mining Tech article here.