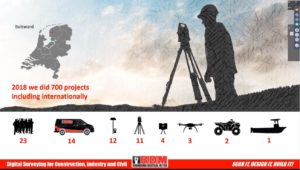

In 2007 Rein Brandsma founded his own surveying company – Brandsma Digitaal Meten (BDM), a Dutch company specialised in Digital Surveying for Construction, Industry and Civil. Geared with a variety of Leica Geosystems instruments, 12 years later the team has grown with 23 people undertaking 700 local and international projects.

Combining technologies and investing in software

With these measuring and positioning technologies, BDM delivers services to different industries – from land surveying to laser scanning and also UAV mapping. For measuring and stake out points BDM uses the iCON and surveying total stations and terrestrial laser scanners. The company uses UAV systems to map and measure wide areas and perform inspections. When using a UAV, experts connect the system to an RTK base-station so it can use less ground control points.

Besides investing in hardware, BDM is also investing in software. Brandsma’s team uses most Leica Geosystems software solutions to give customers data as soon as possible in the file format of their choice.

Capture, prepare, create and share

Data acquisition and visualisation powered by reality capture creates smart digital realities, helping stakeholders to see and model the elements contributing to a project to make best-informed decisions.

A regular reality capture cycle is:

- Capture data of the physical world with a laser scanner

- Prepare (post-process) data

- Create a model

- Share the project with the desired stakeholders to collaborate and visualise.

During the Field-to-Finish efficiency using ground-breaking solutions from Leica Geosystems webinar Brandsma explains how BDM captures and prepares data and creates models or deliverables shared with stakeholders in collaborative platforms like Leica JetStream and Leica TruView. Through seven exciting projects, Brandsma presented why BDM uses reality capture and how they choose the right laser scanner for each task and when to combine them.

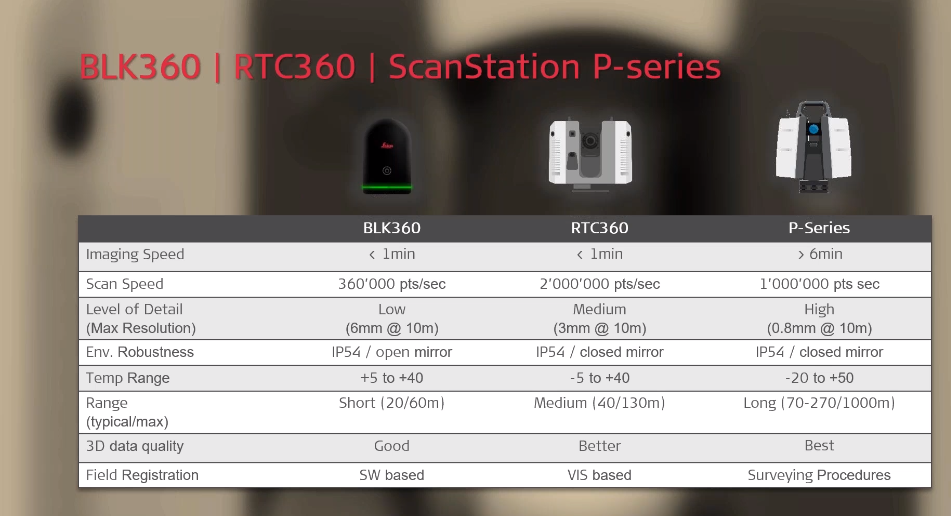

To capture data, BDM uses the Leica BLK360 imaging laser scanner, the Leica RTC360 3D laser scanner or the Leica ScanStation P-Series. According to Brandsma, the most important differences in laser scanners are the range, the 3D data quality, and the on-board real-time dual-axis compensator available in the P-Series. BDM decides what laser scan to use depending on its clients’ needs.

BDM scans small and big objects, just like a 100-metre-tall crane. For one project, where the platform of a big crane had to be replaced, BDM scanned the entire crane and its details in high resolution with the Leica ScanStation P40 (with the option of detail scan) and the lower platforms and the supports with the RTC360.

- Crane scanned with P40 ScanStation

- Base of the crane scanned with RTC360

- Blueprint created with point cloud

After laser scanning, BDM imported and registered data into Leica Cyclone 3D point cloud processing software. Depending on the needs, BDM creates 3D models and/or high-detail blueprints like the image below. BDM also delivers projects through Leica TruView Cloud and uses Leica JetStream Enterprise for collaborative working.

When BDM experts need to laser scan straight into the coordinate system, field crews use a Leica GS16 GNSS smart antenna on top of a tripod to measure the ground control points. Surveyors put data into the total station, export data from the field book and import it into the P40. Experts can then set up the right coordinate system and scan the different areas.

Read more about how Brandsma Digitaal Meten chooses the right laser scanner for the right job in this blog and in this customer profile.

Watch the webinar Field-to-Finish efficiency using ground-breaking solutions from Leica Geosystems and discover more details and reality capture projects.