This three-part series explores how Hexagon’s wide range of products and services contribute to a more sustainable economy, safer workplaces, and a greener planet.

Hexagon’s commitment to a sustainable future

As the significance of Environmental, Social, and Governance (ESG) criteria continues to grow, it is becoming clear that the future of business performance lies in the balance of profit, planet and people. Forward-thinking organisations like Hexagon are rising to the challenge, holding themselves accountable for their impact on the environment and society. Hexagon seeks to have a positive impact through its operations and solutions. Leveraging our innovation potential, we employ cutting-edge technology to drive the shift toward a more sustainable future.

We are also committed to doing more than stating our values – we want to show you how these values manifest themselves, from the long-lasting products we create, to technologies that enhance safety and protect people and the environment, to solutions that help advance the transition to a low-carbon future. This series demonstrates this commitment in action and provides resources for learning more.

Sustainability through safety

Construction sites can be hazardous environments. Accidents can result in injuries, even fatalities, environmental disasters or explosions. Even less severe accidents and damages due to human error can lead to cost overruns and missed delivery deadlines. Leica Geosystems’ safety solutions enhance workplace safety.

Online collaboration

Digital representations of construction sites, such as 3D models or virtual reality simulations, allow workers to conduct virtual site inspections without having to physically visit the site. This reduces the time spent on the construction site, which can help to minimise the risk of accidents and injuries.

Leica Geosystems’ solutions also help collect and analyse data on safety incident and near-misses. This data can be used to identify patterns and trends, allowing companies to implement targeted safety interventions and prevent future incidents.

Collision avoidance

Leica Geosystems offers solutions that make construction sites safer and prevent accidents on construction sites. This Modular Safety Awareness Solution integrates personal alert solutions (Leica iCON PA10) and collision avoidance technology (CAS) with Leica Geosystems Machine Control (iCON PA80). Workers can wear a small device that alerts them as well as the machine operator when they get too close to heavy machinery, preventing collisions and injuries. In addition, the technology can be programmed to automatically slow down or stop the machinery when workers are in close proximity. The comprehensive safety solution is designed to improve visibility between workers and machine operators, preventing machine-to-people, machine-to-machine, and machine-to-object collisions.

Our Machine Control solutions also allow users to create and import 3D Avoidance Zones above and below surface. Leica Geosystems and Xwatch Safety Solutions have jointly developed a new solution to safeguard construction assets and infrastructure on site. A CAN bus communication channel connects the two systems to create one of the world’s first solutions for safety and productivity in a 3D world. This system is unique to Xwatch and Leica Geosystems. The revolutionary combined solution will allow users to create or import 3D avoidance zones directly within the Leica MC1 machine control software.

Utility detection

Contact with underground services can be dangerous for workers. Disturbing underground cables or pipes can lead to terrible and potentially fatal accidents. Even when buried services are documented, minor inaccuracies pose a risk for workers.

Hexagon’s utility detection technologies, including IDS GeoRadar’s ground penetrating radar (GPR) can make worksites safer by allowing workers to locate underground utilities in advance and avoid them during excavation. Using electromagnetic waves, these solutions reliably detect pipes and cables and map subsurface structures and utilities. By making that information immediately and intuitively accessible allows workers to see the location and depth of buried pipes, cables, and other potentially dangerous objects.

By identifying and marking the locations of these utilities, teams can take measures to avoid damaging them, reducing the risk of accidents and injuries but also costly repairs and downtime. Furthermore, many detection technologies are non-destructive, allowing for less intrusive and more sustainable approaches to construction and infrastructure maintenance. Additionally, by minimising the need for excavation and construction work, utility detection can reduce the environmental impact of these activities, such as soil erosion and habitat destruction.

Utility detection technology can help improve safety and efficiency on worksites by enabling workers to work more confidently and with greater accuracy.

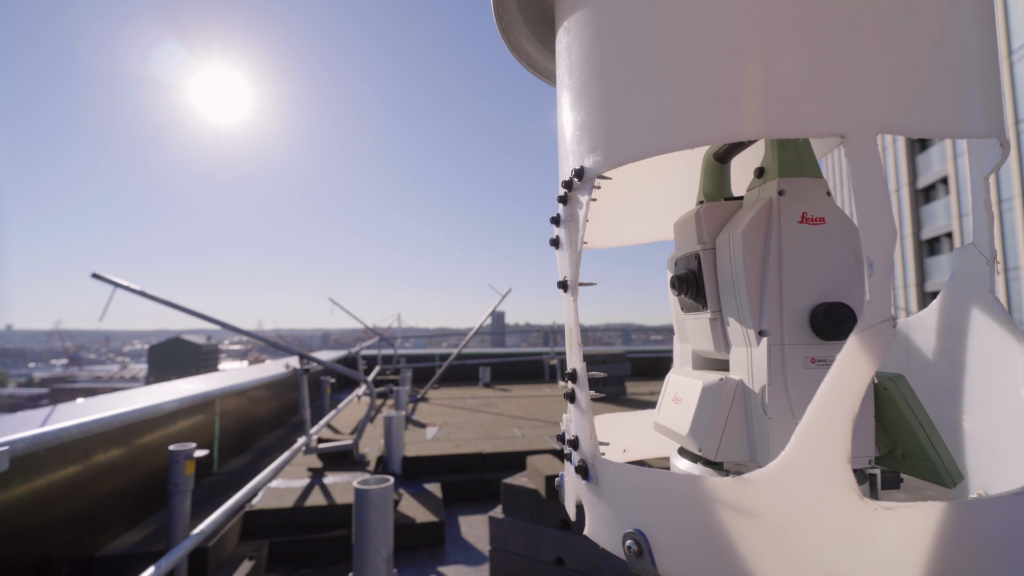

Monitoring movements

Global warming increases the frequency of natural hazards, such as landslides, melting glaciers, avalanches or rockfalls following heavy rainfalls. Ageing infrastructure poses additional risks, especially when put under increased stress due to urbanisation and construction activities. For example, 40% of the United States’ 600,000 bridges are more than 50 years old; one out of eleven is structurally deficient.

Monitoring is fundamental in understanding the risks related to these phenomena and preventing disastrous consequences. Advanced monitoring technologies assess the actual risk and indicate where corrections are impactful or protection measures necessary. They can also identify the precursors of structural failure or early indications of natural hazards to allow evacuating people in time and moving valuable assets to protect them from damage. For example, monitoring the traffic-induced vibration of a bridge helps engineers identify structural problems and close the traffic to repair the bridge or strengthen its structure.

Continuously monitoring the movement of a landslide helps recognise accelerations, which are often precursors of a collapse. Intelligent systems can automatically trigger alarms or prompt protection measures. Geopraevent, part of Hexagon, uses radar to monitor areas for avalanches, debris flows or rockfall. Its systems can, for example, automatically close traffic routes within seconds.

Hexagon owns a unique range of technologies suitable for monitoring and is pursuing the Total Monitoring concept: Our solutions provide advanced, complementary monitoring hardware and software that merges and correlates the data from different sensors and facilitates the interpretation by the user and thus enables experts to make timely and potentially life-saving decisions.

Less exposure to hazardous working conditions

Worker safety can be a major concern for specific surveying tasks. Working in or near trenches, for example, can be hazardous. Any technology that requires fewer people on site helps keep workers safe. With the GS18 I, you can capture the site in images and measure points from them, either in the field or later in the office. This saves surveyors time and enhances their workflows, but more importantly it allows them to stay away from dangerous areas and reduce risky on-site time by measuring from a distance.

Traditional measuring poles require surveyors to level the bubble. Because of its automatic tilt compensation, the award-winning Leica AP20 AutoPole allows users to fully focus on where they walk which increases overall safety. Construction sites with a lot of rebar installed make walking difficult. Any distraction, such as having to keep an eye on the level bubble, can be a safety risk. Also, if you do a survey or layout along a busy road, the AP20 allows you to pay attention to the traffic.

Coastal protection

Surveyors play a critical role in preventing coastal erosion by providing accurate data and expertise to inform coastal management strategies. Our solutions help measure changes in coastal areas to see the impact of erosion. Based on that information, engineers can design mitigation plans to limit further erosion and safeguard people and property.

Remote measurement

3D Laser scanning technology can play a pivotal role in improving safety standards and reducing the risk of accidents. Workers can avoid climbing to dangerous heights or navigating through narrow and precarious spaces to obtain accurate measurements and dimensions. This, in turn, reduces the risk of falls and promotes a safer work environment.

Portable 3D laser scanners are used for onsite surveying and recording data from a safe distance. The technology, for example, allows measuring objects that can be dangerous from the ground level without getting too close or climbing on top of it. Field verifying and scanning from a safe distance will ensure the safety of the workers when sites are unsafe to access.